Page 233 - 05. Subyek Teknik Mesin - Automobile Mechanical and Electrical Systems Automotive Technology Vehicle Maintenance and Repair (Vehicle Maintenance Repr Nv2) by Tom Denton

P. 233

2

Engine systems 217

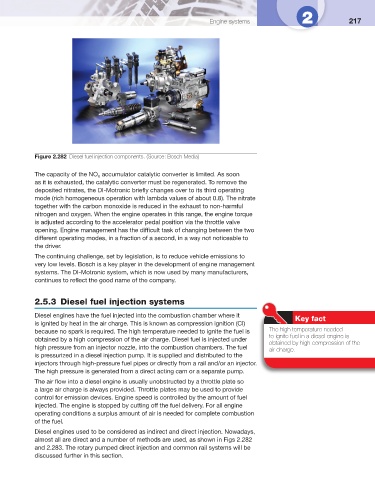

Figure 2.282 Diesel fuel injection components. (Source: Bosch Media)

The capacity of the NO accumulator catalytic converter is limited. As soon

x

as it is exhausted, the catalytic converter must be regenerated. To remove the

deposited nitrates, the DI-Motronic briefl y changes over to its third operating

mode (rich homogeneous operation with lambda values of about 0.8). The nitrate

together with the carbon monoxide is reduced in the exhaust to non-harmful

nitrogen and oxygen. When the engine operates in this range, the engine torque

is adjusted according to the accelerator pedal position via the throttle valve

opening. Engine management has the diffi cult task of changing between the two

different operating modes, in a fraction of a second, in a way not noticeable to

the driver.

The continuing challenge, set by legislation, is to reduce vehicle emissions to

very low levels. Bosch is a key player in the development of engine management

systems. The DI-Motronic system, which is now used by many manufacturers,

continues to refl ect the good name of the company.

2.5.3 Diesel fuel injection systems

Diesel engines have the fuel injected into the combustion chamber where it

Key fact

is ignited by heat in the air charge. This is known as compression ignition (CI)

because no spark is required. The high temperature needed to ignite the fuel is The high temperature needed

to ignite fuel in a diesel engine is

obtained by a high compression of the air charge. Diesel fuel is injected under

obtained by high compression of the

high pressure from an injector nozzle, into the combustion chambers. The fuel

air charge.

is pressurized in a diesel injection pump. It is supplied and distributed to the

injectors through high-pressure fuel pipes or directly from a rail and/or an injector.

The high pressure is generated from a direct acting cam or a separate pump.

The air fl ow into a diesel engine is usually unobstructed by a throttle plate so

a large air charge is always provided. Throttle plates may be used to provide

control for emission devices. Engine speed is controlled by the amount of fuel

injected. The engine is stopped by cutting off the fuel delivery. For all engine

operating conditions a surplus amount of air is needed for complete combustion

of the fuel.

Diesel engines used to be considered as indirect and direct injection. Nowadays,

almost all are direct and a number of methods are used, as shown in Figs 2.282

and 2.283 . The rotary pumped direct injection and common rail systems will be

discussed further in this section.