Page 25 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 25

2.1

Chapter 2.1

Measurement of torque, power,

speed and fuel consumption;

acceptance and type tests,

accuracy of the measurements

A.J. Martyr and M.A. Plint

2.1.1 Introduction almost invariably of the strain gauge type, together with

an appropriate bridge circuit and amplifier. The strain

gauge transducer or ‘load cell’ has the advantage of being

The torque produced by a prime mover under test is

resisted and measured by the dynamometer to which it is extremely stiff, so that no positional adjustment is nec-

connected. The accuracy with which a dynamometer essary, but the disadvantage of a finite fatigue life after

measures both torque and speed is fundamental to all the a (very large) number of load applications. The backlash

other derived measurements made in the test cell. and ‘stiction’-free mounting of the transducer between

In this chapter the principles of torque measurement carcase and base is absolutely critical.

are reviewed and then the types of dynamometer are The trunnion bearings are either a combination of

reviewed in order to assist the purchaser in the selection a ball bearing (for axial location) and a roller bearing

of the most appropriate machine. or hydrostatic type. These bearings operate under

2.1.2 Measurement of torque:

trunnion-mounted (cradle)

machines

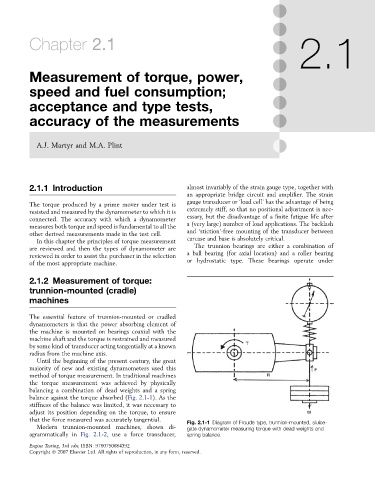

The essential feature of trunnion-mounted or cradled

dynamometers is that the power absorbing element of

the machine is mounted on bearings coaxial with the

machine shaft and the torque is restrained and measured

T

by some kind of transducer acting tangentially at a known

radius from the machine axis.

Until the beginning of the present century, the great

majority of new and existing dynamometers used this F

method of torque measurement. In traditional machines R

the torque measurement was achieved by physically

balancing a combination of dead weights and a spring

balance against the torque absorbed (Fig. 2.1-1). As the

stiffness of the balance was limited, it was necessary to

adjust its position depending on the torque, to ensure W

that the force measured was accurately tangential. Fig. 2.1-1 Diagram of Froude type, trunnion-mounted, sluice-

Modern trunnion-mounted machines, shown di- gate dynamometer measuring torque with dead weights and

agrammatically in Fig. 2.1-2, use a force transducer, spring balance.

Engine Testing, 3rd edn; ISBN: 9780750684392

Copyright Ó 2007 Elsevier Ltd. All rights of reproduction, in any form, reserved.