Page 28 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 28

CH AP TER 2 .1 Measurement of torque, power, speed and fuel consumption

Antenna segments machine in its normal no-load running condition (cooling

water on, etc.) and the calibration arm weight balanced

by equal and opposite force. Dead weights are then

added to produce approximately the rated maximum

torque of the machine. This torque is calculated and the

Rotor digital indicator set to this value.

The weights are removed, the zero reading noted, and

weights are added, preferably in 10 equal increments, the

cell readings being noted. The weights are removed in

reverse order and the readings again noted.

The procedure described above means that the load

cell indicator was set to read zero before any load was

applied (it did not necessarily read zero after the weights

Measuring body Adaptor flange had been added and removed), while it was adjusted to

read the correct maximum torque when the appropriate

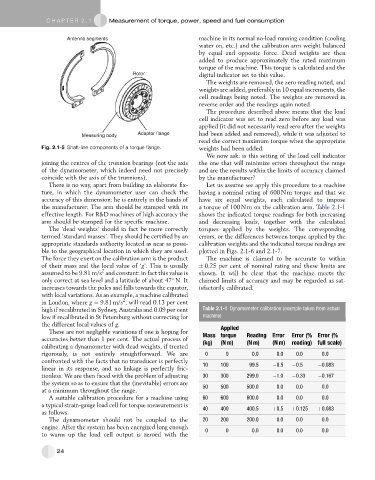

Fig. 2.1-5 Shaft-line components of a torque flange. weights had been added.

We now ask: is this setting of the load cell indicator

joining the centres of the trunnion bearings (not the axis the one that will minimize errors throughout the range

of the dynamometer, which indeed need not precisely and are the results within the limits of accuracy claimed

coincide with the axis of the trunnions). by the manufacturer?

There is no way, apart from building an elaborate fix- Let us assume we apply this procedure to a machine

ture, in which the dynamometer user can check the having a nominal rating of 600 N m torque and that we

accuracy of this dimension: he is entirely in the hands of have six equal weights, each calculated to impose

the manufacturer. The arm should be stamped with its a torque of 100 N m on the calibration arm. Table 2.1-1

effective length. For R&D machines of high accuracy the shows the indicated torque readings for both increasing

arm should be stamped for the specific machine. and decreasing loads, together with the calculated

The ‘dead weights’ should in fact be more correctly torques applied by the weights. The corresponding

termed ‘standard masses’. They should be certified by an errors, or the differences between torque applied by the

appropriate standards authority located as near as possi- calibration weights and the indicated torque readings are

ble to the geographical location in which they are used. plotted in Figs. 2.1-6 and 2.1-7.

The force they exert on the calibration arm is the product The machine is claimed to be accurate to within

of their mass and the local value of ‘g’. This is usually 0.25 per cent of nominal rating and these limits are

2

assumed to be 9.81 m/s and constant: in fact this value is shown. It will be clear that the machine meets the

only correct at sea level and a latitude of about 47 N. It claimed limits of accuracy and may be regarded as sat-

increases towards the poles and falls towards the equator, isfactorily calibrated.

with local variations. As an example, a machine calibrated

2

in London, where g ¼ 9.81 m/s , will read 0.13 per cent

high if recalibrated in Sydney, Australia and 0.09 per cent Table 2.1-1 Dynamometer calibration (example taken from actual

low if recalibrated in St Petersburg without correcting for machine)

the different local values of g.

These are not negligible variations if one is hoping for Applied

accuracies better than 1 per cent. The actual process of Mass torque Reading Error Error (% Error (%

(N m)

(N m)

(kg)

reading) full scale)

(N m)

calibrating a dynamometer with dead weights, if treated

rigorously, is not entirely straightforward. We are 0 0 0.0 0.0 0.0 0.0

confronted with the facts that no transducer is perfectly

10 100 99.5 0.5 0.5 0.083

linear in its response, and no linkage is perfectly fric-

tionless. We are then faced with the problem of adjusting 30 300 299.0 1.0 0.33 0.167

the system so as to ensure that the (inevitable) errors are

50 500 500.0 0.0 0.0 0.0

at a minimum throughout the range.

A suitable calibration procedure for a machine using 60 600 600.0 0.0 0.0 0.0

a typical strain-gauge load cell for torque measurement is

as follows. 40 400 400.5 þ0.5 þ0.125 þ0.083

The dynamometer should not be coupled to the 20 200 200.0 0.0 0.0 0.0

engine. After the system has been energized long enough 0 0 0.0 0.0 0.0 0.0

to warm up the load cell output is zeroed with the

24