Page 584 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 584

Design and material utilization C HAPTER 18.1

18.1.2.3 Early materials and subsequent

changes

Wood used in conjunction with fabric has been referred

to already and was the construction of the bodywork of

many cars in the 1920s before its replacement by steel.

For outer panels this was of fairly thick gauge between

0.9 and 1.00 mm and much of it destined for the UK

Midlands car plants was produced in the South Wales

steelworks in ingot cast rimming or stabilized grades

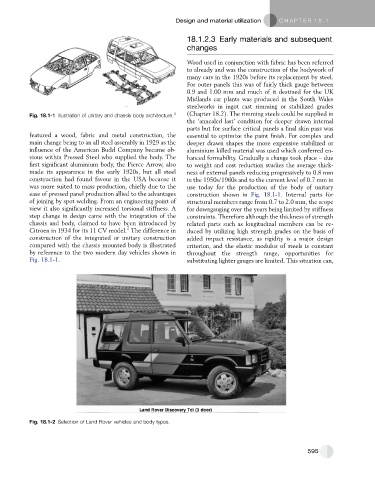

Fig. 18.1-1 Illustration of unitary and chassis body architecture. 3 (Chapter 18.2). The rimming steels could be supplied in

the ‘annealed last’ condition for deeper drawn internal

parts but for surface critical panels a final skin pass was

featured a wood, fabric and metal construction, the essential to optimize the paint finish. For complex and

main change being to an all steel assembly in 1929 as the deeper drawn shapes the more expensive stabilized or

influence of the American Budd Company became ob- aluminium killed material was used which conferred en-

vious within Pressed Steel who supplied the body. The hanced formability. Gradually a change took place – due

first significant aluminium body, the Pierce Arrow, also to weight and cost reduction studies the average thick-

made its appearance in the early 1920s, but all steel ness of external panels reducing progressively to 0.8 mm

construction had found favour in the USA because it in the 1950s/1960s and to the current level of 0.7 mm in

was more suited to mass production, chiefly due to the use today for the production of the body of unitary

ease of pressed panel production allied to the advantages construction shown in Fig. 18.1-1. Internal parts for

of joining by spot welding. From an engineering point of structural members range from 0.7 to 2.0 mm, the scope

view it also significantly increased torsional stiffness. A for downgauging over the years being limited by stiffness

step change in design came with the integration of the constraints. Therefore although the thickness of strength

chassis and body, claimed to have been introduced by related parts such as longitudinal members can be re-

2

Citroen in 1934 for its 11 CV model. The difference in duced by utilizing high strength grades on the basis of

construction of the integrated or unitary construction added impact resistance, as rigidity is a major design

compared with the chassis mounted body is illustrated criterion, and the elastic modulus of steels is constant

by reference to the two modern day vehicles shown in throughout the strength range, opportunities for

Fig. 18.1-1. substituting lighter gauges are limited. This situation can,

Fig. 18.1-2 Selection of Land Rover vehicles and body types.

595