Page 586 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 586

Design and material utilization C HAPTER 18.1

All figures relate to the body structure

and exclude fenders and closures

Mass (kg) 307

Torsional stiffness (Nm/deg) 17 360

First torsion (Hz) 36

First bending (Hz) 52

Number of parts 317

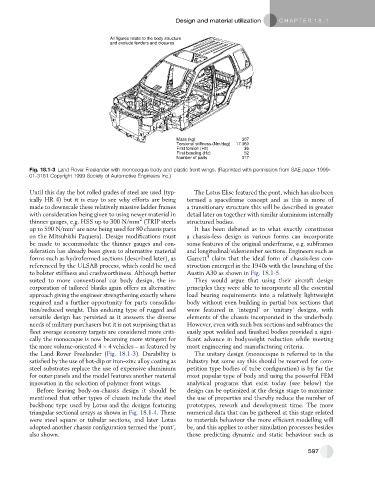

Fig. 18.1-3 Land Rover Freelander with monocoque body and plastic front wings. (Reprinted with permission from SAE paper 1999-

01-3181 Copyright 1999 Society of Automotive Engineers Inc.)

Until this day the hot rolled grades of steel are used (typ- The Lotus Elise featured the punt, which has also been

ically HR 4) but it is easy to see why efforts are being termed a spaceframe concept and as this is more of

made to downscale these relatively massive ladder frames a transitionary structure this will be described in greater

with consideration being given to using newer material in detail later on together with similar aluminium internally

2

thinner gauges, e.g. HSS up to 300 N/mm (TRIP steels structured bodies.

2

up to 590 N/mm are now being used for 80 chassis parts It has been debated as to what exactly constitutes

on the Mitsubishi Paquera). Design modifications must a chassis-less design as various forms can incorporate

be made to accommodate the thinner gauges and con- some features of the original underframe, e.g. subframes

sideration has already been given to alternative material and longitudinal/sidemember sections. Engineers such as

4

forms such as hydroformed sections (described later), as Garrett claim that the ideal form of chassis-less con-

referenced by the ULSAB process, which could be used struction emerged in the 1940s with the launching of the

to bolster stiffness and crashworthiness. Although better Austin A30 as shown in Fig. 18.1-5.

suited to more conventional car body design, the in- They would argue that using their aircraft design

corporation of tailored blanks again offers an alternative principles they were able to incorporate all the essential

approach giving the engineer strengthening exactly where load bearing requirements into a relatively lightweight

required and a further opportunity for parts consolida- body without even building in partial box sections that

tion/reduced weight. This enduring type of rugged and were featured in ‘integral’ or ‘unitary’ designs, with

versatile design has persisted as it answers the diverse elements of the chassis incorporated in the underbody.

needs of military purchasers but it is not surprising that as However, even with such box sections and subframes the

fleet average economy targets are considered more criti- easily spot welded and finished bodies provided a signi-

cally the monocoque is now becoming more stringent for ficant advance in bodyweight reduction while meeting

the more volume-oriented 4 4 vehicles – as featured by most engineering and manufacturing criteria.

the Land Rover Freelander (Fig. 18.1-3). Durability is The unitary design (monocoque is referred to in the

satisfied by the use of hot-dip or iron–zinc alloy coating as industry but some say this should be reserved for com-

steel substrates replace the use of expensive aluminium petition type bodies of tube configuration) is by far the

for outer panels and the model features another material most popular type of body and using the powerful FEM

innovation in the selection of polymer front wings. analytical programs that exist today (see below) the

Before leaving body-on-chassis design it should be design can be optimized at the design stage to maximize

mentioned that other types of chassis include the steel the use of properties and thereby reduce the number of

backbone type used by Lotus and the designs featuring prototypes, rework and development time. The more

triangular sectional arrays as shown in Fig. 18.1-4. These numerical data that can be gathered at this stage related

were steel square or tubular sections, and later Lotus to materials behaviour the more efficient modelling will

adopted another chassis configuration termed the ‘punt’, be, and this applies to other simulation processes besides

also shown. those predicting dynamic and static behaviour such as

597