Page 589 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 589

CHAP TER 1 8. 1 Design and material utilization

Stress

12 element 24 element

mesh mesh

Mesh 1 – 48 Elements

Mesh 2 – 100 Elements

Mesh 3 – 192 Elements

Hook Mesh 4 – 24 Elements

pressure 48 Element Mesh 5 – 12 Elements

mesh

loading

(a) MES 3 and 4

almost coincident

100 Element 192 Element Node position

mesh mesh

(c)

(b)

y

0 σ x

s ix b i c i

c j s my c i

s jx b j 0 c j σ y

s mx b m 0 c m τ xy s mx

1 m

=–

2

s iy 0 c i b i σ y

b j s jy

b i

0 c j b j σ x

s jy

τ xy

0 c m b m j

s my

s jx

i

s ix b m

σ

T

(d) S = C = B σ

c m

s iy

x

3 1 2 1

Axial Planar

3 2 4 2

(e) Repetitive

Cyclic (g)

σ σ

Shape Type Geometry

Point Mass

Line Spring, beam, spar, gap Bilinear Multilinear

ε ε

Area 2D solid, axisymmetric

solid, plate (h)

Curved area Shell

Volume 3D solid

(f)

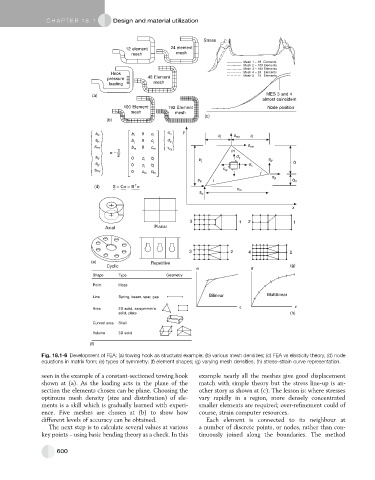

Fig. 18.1-6 Development of FEA: (a) towing hook as structural example; (b) various mesh densities; (c) FEA vs elasticity theory; (d) node

equations in matrix form; (e) types of symmetry; (f) element shapes; (g) varying mesh densities; (h) stress–strain curve representation.

seen in the example of a constant-sectioned towing hook example nearly all the meshes give good displacement

shown at (a). As the loading acts in the plane of the match with simple theory but the stress line-up is an-

section the elements chosen can be plane. Choosing the other story as shown at (c). The lesson is: where stresses

optimum mesh density (size and distribution) of ele- vary rapidly in a region, more densely concentrated

ments is a skill which is gradually learned with experi- smaller elements are required; over-refinement could of

ence. Five meshes are chosen at (b) to show how course, strain computer resources.

different levels of accuracy can be obtained. Each element is connected to its neighbour at

The next step is to calculate several values at various a number of discrete points, or nodes, rather than con-

key points – using basic bending theory as a check. In this tinuously joined along the boundaries. The method

600