Page 594 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 594

Design and material utilization C HAPTER 18.1

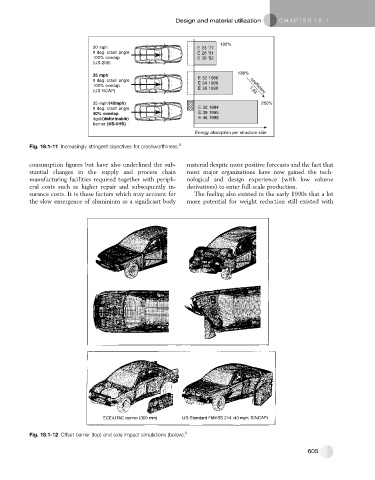

100%

30 mph E 23 ’77

0 deg. crash angle E 28 ’81

100% overlap E 30 ’82

(US-208)

136%

35 mph E 32 1986

0 deg. crash angle

E 34 1988

100% overlap E 36 1990 coefficient

(US-NCAP) 1.83

35 mph/(40mph) 250%

0 deg. crash angle E 38 1994

40% overlap E 39 1995

rigid/(deformable) E 46 1998

barrier (US-IIHS)

Energy absorption per structure side

Fig. 18.1-11 Increasingly stringent objectives for crashworthiness. 6

consumption figures but have also underlined the sub- material despite more positive forecasts and the fact that

stantial changes in the supply and process chain most major organizations have now gained the tech-

manufacturing facilities required together with periph- nological and design experience (with low volume

eral costs such as higher repair and subsequently in- derivatives) to enter full-scale production.

surance costs. It is these factors which may account for The feeling also existed in the early 1990s that a lot

the slow emergence of aluminium as a significant body more potential for weight reduction still existed with

Fig. 18.1-12 Offset barrier (top) and side impact simulations (below). 6

605