Page 595 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 595

CHAP TER 1 8. 1 Design and material utilization

Intermittent engine Waste energy

shutdown exploitation

Ancillary components

Optimum

operating point

of the engine

Drivetrain

efficiency

Aerodynamic

Rolling resistance Vehicle weight

of tyres

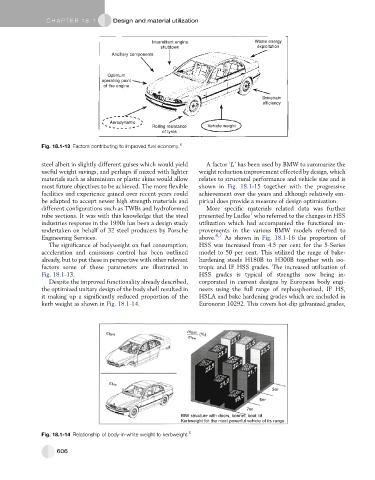

Fig. 18.1-13 Factors contributing to improved fuel economy. 6

steel albeit in slightly different guises which would yield A factor ‘L’ has been used by BMW to summarize the

useful weight savings, and perhaps if mixed with lighter weight reduction improvement effected by design, which

materials such as aluminium or plastic skins would allow relates to structural performance and vehicle size and is

most future objectives to be achieved. The more flexible shown in Fig. 18.1-15 together with the progressive

facilities and experience gained over recent years could achievement over the years and although relatively em-

be adapted to accept newer high strength materials and pirical does provide a measure of design optimization.

different configurations such as TWBs and hydroformed More specific materials related data was further

7

tube sections. It was with this knowledge that the steel presented by Ludke who referred to the changes in HSS

industries response in the 1990s has been a design study utilization which had accompanied the functional im-

undertaken on behalf of 32 steel producers by Porsche provements in the various BMW models referred to

Engineering Services. above. 6,7 As shown in Fig. 18.1-16 the proportion of

The significance of bodyweight on fuel consumption, HSS was increased from 4.5 per cent for the 5-Series

acceleration and emissions control has been outlined model to 50 per cent. This utilized the range of bake-

already, but to put these in perspective with other relevant hardening steels H180B to H300B together with iso-

factors some of these parameters are illustrated in tropic and IF HSS grades. The increased utilization of

Fig. 18.1-13. HSS grades is typical of strengths now being in-

Despite the improved functionality already described, corporated in current designs by European body engi-

the optimized unitary design of the body shell resulted in neers using the full range of rephosphorized, IF HS,

it making up a significantly reduced proportion of the HSLA and bake hardening grades which are included in

kerb weight as shown in Fig. 18.1-14. Euronorm 10292. This covers hot-dip galvanized grades,

m BIW

m BIW (%)

m Kw

m Kw

3er

5er

7er

BIW structure with doors, bonnet, boot lid

Kerbweight for the most powerful vehicle of its range

Fig. 18.1-14 Relationship of body-in-white weight to kerbweight. 6

606