Page 597 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 597

CHAP TER 1 8. 1 Design and material utilization

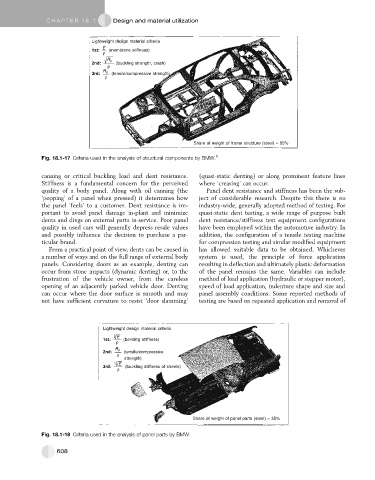

Lightweight design material criteria

E

1st: (membrane stiffness)

ρ

R p

2nd: (buckling strength, crash)

ρ

3rd: R p (tensile/compressive strength)

ρ

Share of weight of frame structure (steel) ≈ 65%

Fig. 18.1-17 Criteria used in the analysis of structural components by BMW. 6

canning or critical buckling load and dent resistance. (quasi-static denting) or along prominent feature lines

Stiffness is a fundamental concern for the perceived where ‘creasing’ can occur.

quality of a body panel. Along with oil canning (the Panel dent resistance and stiffness has been the sub-

‘popping’ of a panel when pressed) it determines how ject of considerable research. Despite this there is no

the panel ‘feels’ to a customer. Dent resistance is im- industry-wide, generally adopted method of testing. For

portant to avoid panel damage in-plant and minimize quasi-static dent testing, a wide range of purpose built

dents and dings on external parts in-service. Poor panel dent resistance/stiffness test equipment configurations

quality in used cars will generally depress resale values have been employed within the automotive industry. In

and possibly influence the decision to purchase a par- addition, the configuration of a tensile testing machine

ticular brand. for compression testing and similar modified equipment

From a practical point of view, dents can be caused in has allowed suitable data to be obtained. Whichever

a number of ways and on the full range of external body system is used, the principle of force application

panels. Considering doors as an example, denting can resulting in deflection and ultimately plastic deformation

occur from stone impacts (dynamic denting) or, to the of the panel remains the same. Variables can include

frustration of the vehicle owner, from the careless method of load application (hydraulic or stepper motor),

opening of an adjacently parked vehicle door. Denting speed of load application, indenture shape and size and

can occur where the door surface is smooth and may panel assembly conditions. Some reported methods of

not have sufficient curvature to resist ‘door slamming’ testing are based on repeated application and removal of

Lightweight design material criteria

3 E

1st: (bending stiffness)

ρ

R p

2nd: (tensile/compressive

ρ

strength)

E

3rd: (buckling stiffness of sheets)

ρ

Share of weight of panel parts (steel) ≈ 35%

Fig. 18.1-18 Criteria used in the analysis of panel parts by BMW.

608