Page 596 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 596

Design and material utilization C HAPTER 18.1

⎡ kg ⎤

×

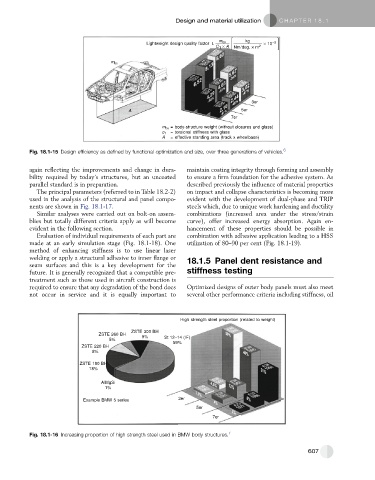

Lightweight design quality factor L m bs ⎢ 10 –3 ⎥

C T × A ⎢ ⎣ Nm/deg. m 2 ⎦ ⎥

×

m bs

3er

A 5er

7er

m bs = body-structure weight (without closures and glass)

c T = torsional stiffness with glass

A = effective standing area (track x wheelbase)

Fig. 18.1-15 Design efficiency as defined by functional optimization and size, over three generations of vehicles. 6

again reflecting the improvements and change in dura- maintain coating integrity through forming and assembly

bility required by today’s structures, but an uncoated to ensure a firm foundation for the adhesive system. As

parallel standard is in preparation. described previously the influence of material properties

The principal parameters (referred to in Table 18.2-2) on impact and collapse characteristics is becoming more

used in the analysis of the structural and panel compo- evident with the development of dual-phase and TRIP

nents are shown in Fig. 18.1-17. steels which, due to unique work hardening and ductility

Similar analyses were carried out on bolt-on assem- combinations (increased area under the stress/strain

blies but totally different criteria apply as will become curve), offer increased energy absorption. Again en-

evident in the following section. hancement of these properties should be possible in

Evaluation of individual requirements of each part are combination with adhesive application leading to a HSS

made at an early simulation stage (Fig. 18.1-18). One utilization of 80–90 per cent (Fig. 18.1-19).

method of enhancing stiffness is to use linear laser

welding or apply a structural adhesive to inner flange or 18.1.5 Panel dent resistance and

seam surfaces and this is a key development for the

future. It is generally recognized that a compatible pre- stiffness testing

treatment such as those used in aircraft construction is

required to ensure that any degradation of the bond does Optimized designs of outer body panels must also meet

not occur in service and it is equally important to several other performance criteria including stiffness, oil

High strength steel proportion (related to weight)

ZSTE 300 BH

ZSTE 260 BH 9%

5% St 12–14 (IF)

59%

ZSTE 220 BH

8%

ZSTE 180 BH

18%

AIMgSi

1%

3er

Example BMW 5 series

5er

7er

Fig. 18.1-16 Increasing proportion of high strength steel used in BMW body structures. 7

607