Page 593 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 593

CHAP TER 1 8. 1 Design and material utilization

Global natural mode (complete vehicle)

1st torsion [Hz]

1st bending [Hz]

3er 3er

5er 5er

7er 7er

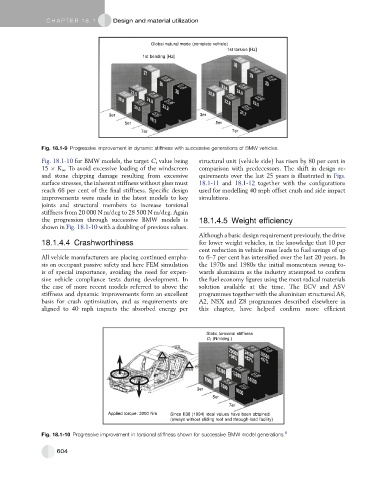

Fig. 18.1-9 Progressive improvement in dynamic stiffness with successive generations of BMW vehicles.

Fig. 18.1-10 for BMW models, the target C t value being structural unit (vehicle side) has risen by 80 per cent in

15 K w . To avoid excessive loading of the windscreen comparison with predecessors. The shift in design re-

and stone chipping damage resulting from excessive quirements over the last 25 years is illustrated in Figs.

surface stresses, the inherent stiffness without glass must 18.1-11 and 18.1-12 together with the configurations

reach 66 per cent of the final stiffness. Specific design used for modelling 40 mph offset crash and side impact

improvements were made in the latest models to key simulations.

joints and structural members to increase torsional

stiffness from 20 000 N m/deg to 28 500 N m/deg. Again

the progression through successive BMW models is 18.1.4.5 Weight efficiency

shown in Fig. 18.1-10 with a doubling of previous values.

Although a basic design requirement previously, the drive

18.1.4.4 Crashworthiness for lower weight vehicles, in the knowledge that 10 per

cent reduction in vehicle mass leads to fuel savings of up

All vehicle manufacturers are placing continued empha- to 6–7 per cent has intensified over the last 20 years. In

sis on occupant passive safety and here FEM simulation the 1970s and 1980s the initial momentum swung to-

is of special importance, avoiding the need for expen- wards aluminium as the industry attempted to confirm

sive vehicle compliance tests during development. In the fuel economy figures using the most radical materials

the case of more recent models referred to above the solution available at the time. The ECV and ASV

stiffness and dynamic improvements form an excellent programmes together with the aluminium structured A8,

basis for crash optimization, and as requirements are A2, NSX and Z8 programmes described elsewhere in

aligned to 40 mph impacts the absorbed energy per this chapter, have helped confirm more efficient

Static torsional stiffness

C T (Nm/deg.)

3er

5er

7er

Applied torque: 3000 Nm Since E38 (1994) ideal values have been obtained.

(always without sliding roof and through-load facility)

Fig. 18.1-10 Progressive improvement in torsional stiffness shown for successive BMW model generations. 6

604