Page 670 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 670

Vehicle refinement: Purpose and targets C HAPTER 20.1

1

testing, the PDS will routinely include separate airborne a maximum of 115 dBA at 6000 rev min . The

noisetargets forcertaincomponentsorvehiclesubsystems. adoption of this target is likely to result in an intake

The most common targets relate to engine-radiated noise, level of 63 dBA during an EC type approval test (as

intake noise and exhaust noise. required by the targets shown in Table 20.1-3)

without relying on any attenuation offered by the

20.1.6.2.1 Engine-radiated noise targets vehicle bodyshell.

These are normally set in terms of sound power level. A firing order sound pressure level of 105 dB (lin) at

European engine suppliers are now required by law to low drive-away engine speeds (full load), a level of

measure and declare the sound power emissions of their 100 dB (lin) at moderate engine speeds and a level of

engines. This makes a comparison between competitor 105 dB (lin) at high engine speeds.

engines easy. Sound pressure levels for other higher orders of

Engine-radiated noise targets are more important for 95 dB (lin) at low drive-away engine speeds (full

diesel engines than for gasoline engines as the various load), a level of 90 dB (lin) at moderate speeds and

type approval tests undertaken around the world demand a level of 95 dB (lin) at high engine speeds.

only quite low engine speeds where gasoline engines are

generally quiet and rarely cause failure of the test. 20.1.6.2.3 Exhaust tailpipe-radiated noise

Again, it is not possible to adopt a single set of noise targets

targets applicable to all potential engines, but an in- These are commonly set as maximum sound pressure

dicative set is offered in Table 20.1-4. This relates to levels to be recorded at a distance of 500 mm from the

a particular diesel engine used in light European trucks exhaust tailpipe at an angle of incidence of 45 . Common

and sports-utility vehicles. targets are:

An alternative target for a 4.0-litre four-cylinder DI

diesel is offered by Pettitt (1988) at 107 dB re 10 12 W. An overall A-weighted sound pressure level of

1

An alternative (and rather different) noise source ranking 82 dBA at 1000 rev min wide-open throttle (full

1

is offered for a six-cylinder diesel engine by Beidl et al. load) rising at a rate of 5 dBA per 1000 rev min to

1

(1999). a maximum of 107 dBA at 6000 rev min . The

adoption of this target is likely to result in an exhaust

level of 69 dBA during a type approval test (as

20.1.6.2.2 Intake orifice-radiated noise targets required by the targets shown in Table 20.1-3).

These are commonly set as maximum sound pressure A firing order sound pressure level of 120 dB (lin) at

levels to be recorded at a distance of 100 mm from the low drive-away engine speeds (full load), a level of

intake orifice at an angle of incidence of 90 . Common 100 dB (lin) at moderate speeds and a level of

targets are: 115 dB (lin) at high engine speeds.

An overall A-weighted sound pressure level of Sound pressure levels for other higher orders of

90 dBA at 1000 rev min 1 wide-open throttle (full 105 dB (lin) at low drive-away engine speeds (full

load) rising at a rate of 5 dBA per 1000 rev min 1 to load), a level of 95 dB (lin) at moderate speeds and

a level of 105 dB (lin) at high engine speeds.

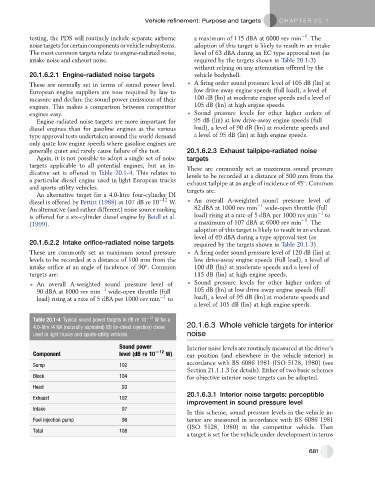

Table 20.1-4 Typical sound power targets in dB re 10 12 W for a

4.0-litre I4 NA (naturally aspirated) IDI (in-direct injection) diesel 20.1.6.3 Whole vehicle targets for interior

used in light trucks and sports-utility vehicles noise

Sound power Interior noise levels are routinely measured at the driver’s

Component level (dB re 10 L12 W) ear position (and elsewhere in the vehicle interior) in

accordance with BS 6086 1981 (ISO 5128, 1980) (see

Sump 102

Section 21.1.1.3 for details). Either of two basic schemes

Block 104 for objective interior noise targets can be adopted.

Head 93

20.1.6.3.1 Interior noise targets: perceptible

Exhaust 102

improvement in sound pressure level

Intake 97

In this scheme, sound pressure levels in the vehicle in-

Fuel injection pump 96 terior are measured in accordance with BS 6086 1981

(ISO 5128, 1980) in the competitor vehicle. Then

Total 108

a target is set for the vehicle under development in terms

681