Page 68 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 68

Emissions control CHAPTER 3.1

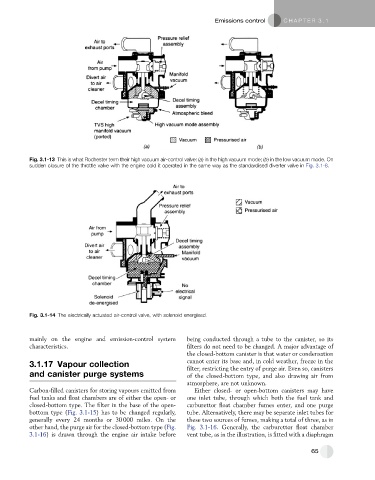

Fig. 3.1-13 This is what Rochester term their high vacuum air-control valve: (a) in the high vacuum mode; (b) in the low vacuum mode. On

sudden closure of the throttle valve with the engine cold it operated in the same way as the standardised diverter valve in Fig. 3.1-8.

Fig. 3.1-14 The electrically actuated air-control valve, with solenoid energised.

mainly on the engine and emission-control system being conducted through a tube to the canister, so its

characteristics. filters do not need to be changed. A major advantage of

the closed-bottom canister is that water or condensation

cannot enter its base and, in cold weather, freeze in the

3.1.17 Vapour collection

filter, restricting the entry of purge air. Even so, canisters

and canister purge systems of the closed-bottom type, and also drawing air from

atmosphere, are not unknown.

Carbon-filled canisters for storing vapours emitted from Either closed- or open-bottom canisters may have

fuel tanks and float chambers are of either the open- or one inlet tube, through which both the fuel tank and

closed-bottom type. The filter in the base of the open- carburettor float chamber fumes enter, and one purge

bottom type (Fig. 3.1-15) has to be changed regularly, tube. Alternatively, there may be separate inlet tubes for

generally every 24 months or 30 000 miles. On the these two sources of fumes, making a total of three, as in

other hand, the purge air for the closed-bottom type (Fig. Fig. 3.1-16. Generally, the carburettor float chamber

3.1-16) is drawn through the engine air intake before vent tube, as in the illustration, is fitted with a diaphragm

65