Page 763 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 763

CHAP TER 2 2. 1 Exterior noise: Assessment and control

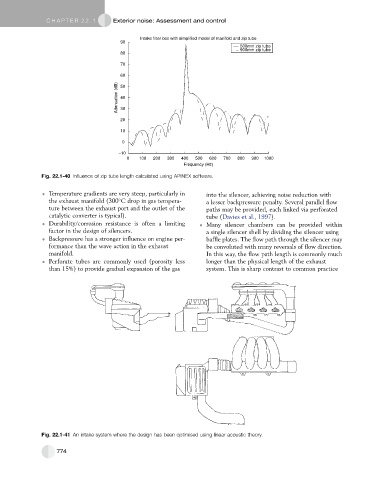

Intake filter box with simplified model of manifold and zip tube

90

500mm zip tube

900mm zip tube

80

70

60

Attenuation (dB) 40

50

30

20

10

0

–10

0 100 200 300 400 500 600 700 800 900 1000

Frequency (Hz)

Fig. 22.1-40 Influence of zip tube length calculated using APINEX software.

Temperature gradients are very steep, particularly in into the silencer, achieving noise reduction with

the exhaust manifold (300 C drop in gas tempera- a lesser backpressure penalty. Several parallel flow

ture between the exhaust port and the outlet of the paths may be provided, each linked via perforated

catalytic converter is typical). tube (Davies et al., 1997).

Durability/corrosion resistance is often a limiting Many silencer chambers can be provided within

factor in the design of silencers. a single silencer shell by dividing the silencer using

Backpressure has a stronger influence on engine per- baffle plates. The flow path through the silencer may

formance than the wave action in the exhaust be convoluted with many reversals of flow direction.

manifold. In this way, the flow path length is commonly much

Perforate tubes are commonly used (porosity less longer than the physical length of the exhaust

than 15%) to provide gradual expansion of the gas system. This is sharp contrast to common practice

Fig. 22.1-41 An intake system where the design has been optimised using linear acoustic theory.

774