Page 307 - Battery Reference Book

P. 307

2714 High-temperature thermally activated primary batteries

27.1.2 Configurations

Thermal batteries are manufactured in a wide

range of configurations to suit various types of

application. Some of the configurations available

from Catalyst Research Corporation are illustrated in

Figures 27.2-27.4.

Figure 27.2 shows the cell configuration of the cup

cell design. This was the first thermal battery design

used in production. The cup cell features a common

anode and two depolarizer pads, thereby doubling

the cell area. The eutectic lithium chloride-potassium

chloride electrolyte is impregnated on to glass tape to

serve as a separator. These are solidified and die-cut Figure 27.3 Construction of a tungstic oxide open cell (Courtesy

to fit the cell. The heat source is zirconium-barium of Catalyst Research Corporation)

chromate, which forms an insulating ceramic mass on

combustion. A cathode lead on the periphery of the Potassium dichromate depolarizer is used in an open

cell serves as an intercell connector. Tungstic oxide cell, with lithium chloride-potassium chloride impreg-

and calcium chromate depolarizers are commonly used nated on glass tape. This depolarizer allows very high

in this design. The active positive material is often current density for fractions of seconds to about 5 s.

mixed with materials such as glass and quartz fibres

and formed paper-thin to fit the cell.

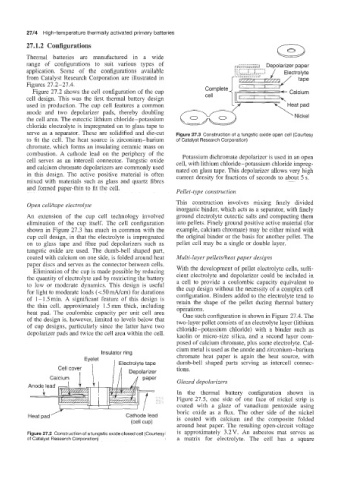

Pellet-type construction

This construction involves mixing finely divided

Open cellhape electrolyte

inorganic binder, which acts as a separator, with finely

An extension of the cup cell technology involved ground electrolyte eutectic salts and compacting them

elimination of the cup itself. The cell configuration into pellets. Finely ground positive active material (for

shown in Figure 27.3 has much in common with the example, calcium chromate) may be either mixed with

cup cell design, in that the electrolyte is impregnated the original binder or the basis for another pellet. The

on to glass tape and fibre pad depolarizers such as pellet cell may be a single or double layer.

tungstic oxide are used. The dumb-bell shaped part,

coated with calcium on one side, is folded around heat Multi-layer pelletsheat paper designs

paper discs and serves as the connector between cells.

Elimination of the cup is made possible by reducing With the development of pellet electrolyte cells, suffi-

the quantity of electrolyte and by restricting the battery cient electrolyte and depolarizer could be included in

to low or moderate dynamics. This design is useful a cell to provide a coulombic capacity equivalent to

the cup design without the necessity of a complex cell

for light to moderate loads (<50 mA/cm) for durations configuration. Binders added to the electrolyte tend to

of 1-1.5min. A significant feature of this design is retain the shape of the pellet during thermal battery

the thin cell, approximately 1.5 mm thick, including operations.

heat pad. The coulombic capacity per unit cell area One such configuration is shown in Figure 27.4. The

of the design is, however, limited to levels below that two-layer pellet consists of an electrolyte layer (lithium

of cup designs, particularly since the latter have two chloride-potassium chloride) with a binder such as

depolarizer pads and twice the cell area within the cell. kaolin or micro-size silica, and a second layer com-

posed of calcium chromate, plus some electrolyte. Cal-

cium metal is used as the anode and zirconium-barium

Insulator ring

chromate heat paper is again the heat source, with

dumb-bell shaped parts serving as intercell connec-

tions.

Glazed depolarizers

In the thermal battery configuration shown in

Figure 27.5, one side of one face of nickel strip is

coated with a glaze of vanadium pentoxide using

boric oxide as a flux. The other side of the nickel

/’

Heat pad Cathode lead is coated with calcium and the composite folded

(cell cup)

around heat paper. The resulting open-circuit voltage

Figure 27.2 Construction of a tungstic oxide closed cell (Courtesy is approximately 3.2V. An asbestos mat serves as

of Catalyst Research Corporation) a matrix for electrolyte. The cell has a square