Page 308 - Battery Reference Book

P. 308

Calcium anode-based thermal batteries 27/5

I , Heat paper

V205-B203 glaze

v2°5 +

eutectic

Eutectic Three-layer

LiCI-KCI I pellet

+ CaCrO, eutectic ' Magnesium J

powder

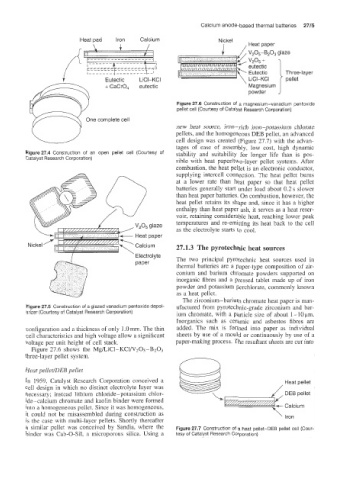

Figure 27.6 Construction of a magnesium-vanadium pentoxide

pellet cell (Courtesy of Catalyst Research Corporation)

One complete cell

new heat source, iron-rich iron-potassium chlorate

pellets, and the homogeneous DEB pellet, an advanced

cell design was created (Figure 27.7) with the advan-

tages of ease of assembly, low cost, high dynamic

Figure 27.4 Consrruction of an open pellet cell (Courtesy of stability and suitability for longer life than is pos-

Catalyst Research Corporation) sible with heat paper/two-layer pellet systems. After

combustion, the heat pellet is an electronic conductor,

supplying intercell connection. The heat pellet burns

at a lower rate than heat paper so that heat pellet

batteries generally start under load about 0.2 s slower

than heat paper batteries. On combustion, however, the

heat pellet retains its shape and, since it has a higher

enthalpy than heat paper ash, it serves as a heat reser-

voir, retaining considerable heat, reaching lower peak

temperatures and re-emitting its heat back to the cell

as the electrolyte starts to cool.

27.1.3 The pyrotechnic heat sources

The two principal pyrotechnic heat sources used in

thermal batteries are a paper-type composition of zir-

conium and barium chromate powders supported on

inorganic fibres and a pressed tablet made up of iron

powder and potassium perchlorate, commonly known

as a heat pellet.

The zirconium-barium chromate heat paper is man-

Figure 27.5 Construction of a glazed vanadium pentoxide depol- ufactured from pyrotechnic-grade zirconium and bar-

arizer (Courtesy of Catalyst Research Corporation) ium chromate, with a particle size of about l-lOpm.

Inorganics such as ceramic and asbestos fibres are

configuration and a thickness of only 1 .O mm. The thin added. The mix is formed into paper as individual

cell characteristics and high voltage allow a significant sheets by use of a mould or continuously by use of a

voltage per unit height of cell stack. paper-making process. The resultant sheets are cut into

Figure 27.6 shows the Mg/LiCl-KCW205-B203

three-layer pellet system.

Heat pellet/DEB pellet

In 1959, Catalyst Research Corporation conceived a

cell design in which no distinct electrolyte layer was

necessary; instead lithium chloride-potassium chlor- L

ide-calcium chromate and kaolin binder were formed

Salciun

into a homogeneous pellet. Since it was homogeneous, '

it could not be misassembled during construction as Iron

is the case with multi-layer pellets. Shortly thereafter

a similar pellet was conceived by Sandia, where the Figure 27.7 Construction of a heat pellet-DEB pellet cell (Cour-

binder was Cab-0-Sil, a microporous silica. Using a tesy of Catalyst Research Corporation)