Page 335 - Biaxial Multiaxial Fatigue and Fracture

P. 335

Influence of Defects on Fatigue Life of Aluminium Pressure Diecastings 319

4. ASM INTERNATIONAL (1 992). Casting, ASM Handbook, Metals Handbook, Formerly

Ninth Edition, Volume 15, ASM International, Materials Park, Ohio, U.S.A.

5. Tsumagari, N., Brevick, J. R., Mobley, C. E. (1998). Control of Microstructures in

Aluminium Diecastings, AFS Transactions, 15-20, Milwaukee, Wisconsin, Ohio State

University, Columbus.

6. Backerud, L., Chai, G. and Tamminen, J. (1990). AFS/SKANALUMINIVM: Solidijkation

Characteristics of Aluminium Alloys, Volume 2, Foundry Alloys.

7. ASTM (1996). E 505, Reference Radiographs for Inspection of Aluminium and

Magwsium Die Castings, Philadelphia, U.S.A.

8. NF (1970). A57- 703, Produits de Fonderie, Pie'ces Moule'es Sous Pression en Aluminium

ou en Alliages Dblluminium, 487-505.

9. Hertzberg, R. W. (1989). Deformation and Fracture Mechanics of Engineering Metals,

John Wiley & Sons, Inc., USA.

10. Viswanathan, S., Duncan, A. J., Sabau, A. S., Han, Q., Porter, W. D. and Riemer, B. W.

(1998). Modeling of Solidification and Porosity in Aluminum Alloy Castings, AFS

Transactions, 4 1 1-41 7, ORNL, Oak Ridge Tennessee.

1 1. Russo, E. (1993). EDIMET: The Atlas of Microstructures of Aluminium Casting Alloys.

Italy.

12. Lino, F. J. (2000). Final Report of the CRAFT Project Darcast (BRST-CT98-5328, Project

No BES2-5637, Coordinated by CIMNE, Barcelona, Spain), INEGI (Institute of

Mechanical Engineering and Industrial Management), Porto, Portugal.

13. Kim, S. B., Yeom, K. D., and Hong C. P. (1 997). Cast Metals 10.

14. Dighe, M. D., Jiang, X. G., Tewari, A., Rahardjo, A. S. B., Gokhale, A. M. (1998).

Quantitative Microstructural Analysis of Microporosity in Cast A356 Aluminium Alloy,

AFS Transactions 13, 181-190.

15. Klansky, J. (1 999). Image Analysis of Aluminum Alloys, Advanced Materials & Processes

7,23-26.

16. ASTM (1982). E 466, Standard Practice for Conducting Constant Amplitude Axial

Fatigue Tests of Metallic Materials, 465-469. Philadelphia, USA.

17. ASTM (1989). E 8M-89b, Standard Test Methods for Tension Testing of Metallic

Materials [Metric], 146-1 60, Philadelphia, USA.

18. ADHESIVES (1995). DIN EN IS0 9664, The Methods for Fatigue Properties qf

Structural Adhesives in Tensile Shear.

19. ASTM (1990). E 468, Standard Practice for Presentation of Constant Amplitude Fatigue

Test Results for Metallic Materials, 475-480, Philadelphia, USA.

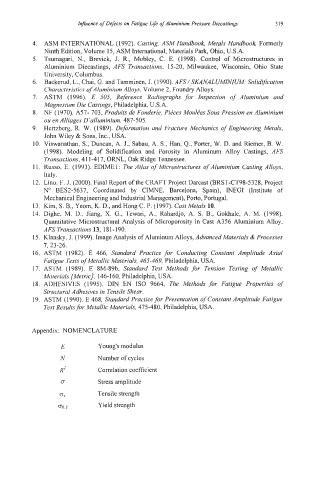

Appendix: NOMENCLATURE

E Young's modulus

N Number of cycles

R' Correlation coefficient

u Stress amplitude

cr Tensile strength

Co.2 Yield strength