Page 225 - Biodegradable Polyesters

P. 225

8.4 Crystalline Structures 203

70000

1: (PLA/15% LMW PCL) (1/1) (DCM/DMF)

2: (PLA/9% HMW PCL) (1/1) (CHCl /MeOH)

3

60000 3: (PLA/15% HMW PCL) (1/1) (CHCl /MeOH)

3

4: (PLA/15% HMW PCL) (1/1) (DCM/DMF)

5: (PLA/15% HMW PCL) (3/1) (DCM/DMF)

101

50000

Intensity (counts) 40000

30000

200 1

2

20000

10000 3

5 4

0

7.5 11.5 15.5 19.5 23.5 27.5 31.5 35.5

2θ (°)

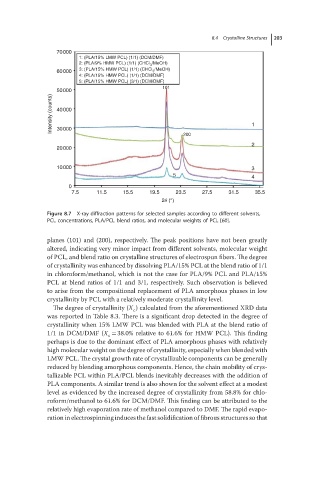

Figure 8.7 X-ray diffraction patterns for selected samples according to different solvents,

PCL concentrations, PLA/PCL blend ratios, and molecular weights of PCL [60].

planes (101) and (200), respectively. The peak positions have not been greatly

altered, indicating very minor impact from different solvents, molecular weight

of PCL, and blend ratio on crystalline structures of electrospun fibers. The degree

of crystallinity was enhanced by dissolving PLA/15% PCL at the blend ratio of 1/1

in chloroform/methanol, which is not the case for PLA/9% PCL and PLA/15%

PCL at blend ratios of 1/1 and 3/1, respectively. Such observation is believed

to arise from the compositional replacement of PLA amorphous phases in low

crystallinity by PCL with a relatively moderate crystallinity level.

The degree of crystallinity (X ) calculated from the aforementioned XRD data

c

was reported in Table 8.3. There is a significant drop detected in the degree of

crystallinity when 15% LMW PCL was blended with PLA at the blend ratio of

1/1 in DCM/DMF (X = 38.0% relative to 61.6% for HMW PCL). This finding

c

perhaps is due to the dominant effect of PLA amorphous phases with relatively

high molecular weight on the degree of crystallinity, especially when blended with

LMW PCL. The crystal growth rate of crystallizable components can be generally

reduced by blending amorphous components. Hence, the chain mobility of crys-

tallizable PCL within PLA/PCL blends inevitably decreases with the addition of

PLA components. A similar trend is also shown for the solvent effect at a modest

level as evidenced by the increased degree of crystallinity from 58.8% for chlo-

roform/methanol to 61.6% for DCM/DMF. This finding can be attributed to the

relatively high evaporation rate of methanol compared to DMF. The rapid evapo-

ration in electrospinning induces the fast solidification of fibrous structures so that