Page 117 - Biofuels Refining and Performance

P. 117

100 Chapter Three

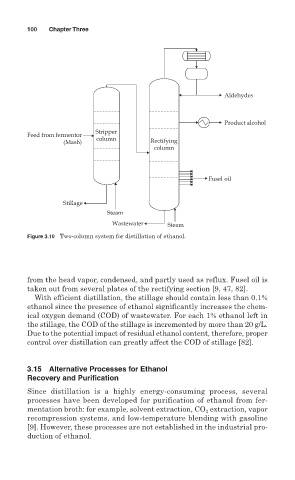

Aldehydes

Product alcohol

Stripper

Feed from fermentor

column

(Mash) Rectifying

column

Fusel oil

Stillage

Steam

Wastewater Steam

Figure 3.10 Two-column system for distillation of ethanol.

from the head vapor, condensed, and partly used as reflux. Fusel oil is

taken out from several plates of the rectifying section [9, 47, 82].

With efficient distillation, the stillage should contain less than 0.1%

ethanol since the presence of ethanol significantly increases the chem-

ical oxygen demand (COD) of wastewater. For each 1% ethanol left in

the stillage, the COD of the stillage is incremented by more than 20 g/L.

Due to the potential impact of residual ethanol content, therefore, proper

control over distillation can greatly affect the COD of stillage [82].

3.15 Alternative Processes for Ethanol

Recovery and Purification

Since distillation is a highly energy-consuming process, several

processes have been developed for purification of ethanol from fer-

mentation broth: for example, solvent extraction, CO extraction, vapor

2

recompression systems, and low-temperature blending with gasoline

[9]. However, these processes are not established in the industrial pro-

duction of ethanol.