Page 106 - Biofuels for a More Sustainable Future

P. 106

12.80kWh

86.43kWh

2.54kWh

33.60kg

1900kJ/kmol a

0.3kWh/

kg st /

8.1kWh/

and

5.97

(180°C

4.8bar):

Electrical:

Electrical:

Electrical:

MW th

kmol a

kg O2

Steam

40bar.

acid

and

1250°Cto

syngas

Gasification

1150°C

form

to

for

22

of

purity

syngas

could

compounds

from

from

800°C

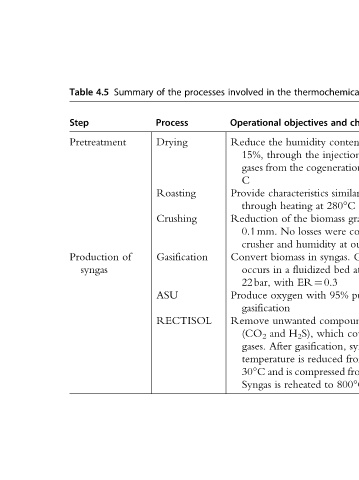

thermochemical route Consumption 1t b for consumption Unit characteristics and 26.00kWh kWh/t b 26 Electrical: to 50% from content exhaust of injection the 260° at boiler cogeneration 4.90kWh 30kJ/kg Electrical: charcoal, to similar 2h for 280°C at 41.16kWh kWh/t b 70 Electrical: to granulometry b

at

syngas.

bed

95%

gasification,

compressed

which

reduced

ER¼0.3

to

fluidized

with

in

the objectives humidity through the characteristics heating the of No and biomass a in with oxygen unwanted H 2 S), and After is is reheated is

in the from through 0.1mm. crusher gasification temperature and

involved Operational Reduce 15%, gases C Provide Reduction Convert occurs 22bar, Produce Remove (CO 2 gases. 30°C Syngas

processes

the Process Drying Roasting Crushing Gasification RECTISOL

of ASU

Summary of

4.5 Pretreatment Production syngas

Table Step