Page 108 - Biofuels for a More Sustainable Future

P. 108

0.24kWh

9.40kWh

206.80kg

14.31g

1t b

for

140kJ/kg syngas

600°C):

350°C)

3kJ/kg syngas

kg steam /kg syngas

consumption

e

e

(22bar

(15bar

Electrical:

Electrical:

0.06

Steam

Steam

Unit

and

and

the

H 2 /

the

characteristics

800°C

steps:

H 2

350°C

the

and

the

into

the

two

in

and

that

injected,

at

between

syngas

injected

reactor

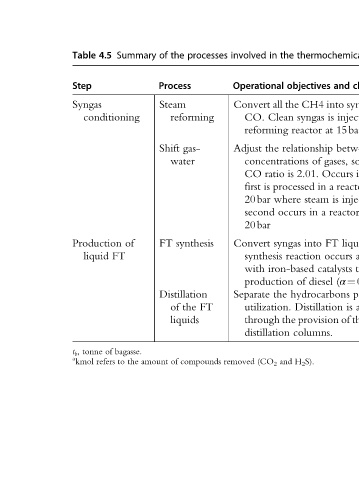

thermochemical 96 route—cont’d Consumption Biofuels for a More Sustainable Future and 200°C at reactor a in 2.66kWh 31kJ/kg syngas Electrical: The liquids. FT into 220°C 25bar, at occurs the maximize to catalysts (α¼0.88) diesel 31.0kJ/kg syngas, MJ/ 1.95 Thermal: for produced hydrocarbons kg syngas accompli

in

15bar

so

Occurs

and

gases,

into

is

is

a

at

steam

in

syngas

CH4

of

the objectives the Clean reactor relationship 2.01. is processed where occurs syngas reaction iron-based of the H 2 S). and

in all reforming the concentrations ratio is synthesis production utilization. through distillation (CO 2

involved Operational Convert CO. Adjust CO first 20bar second 20bar Convert with Separate removed

processes synthesis FT compounds

the Process Steam reforming gas- water Distillation the of liquids of

of Shift FT amount

Summary of bagasse. the to

4.5 conditioning Production FT liquid of refers

Table Step Syngas tonne t b , a kmol