Page 113 - Biofuels for a More Sustainable Future

P. 113

100 Biofuels for a More Sustainable Future

Table 4.9 Amounts of products involved in each study case

Products Base Zero E2G B2G FT BGT

Ethanol (liters/h) 10,192.2 0 30,576.6 0 0

Butanol (liters/h) 3049.9 0 0 11,714.6 0 0

Acetone (liters/h) 1072.8 0 0 3215.4 0 0

Ethanol (liters/h) 273.1 0 0 819.2 0 0

Gasoline (liters/h) 1686.1 0 0 0 8093.2 0

Diesel (liters/h) 1596.4 0 0 0 7662.6 0

Waxes (liters/h) 857.5 0 0 0 4116.0 0

Fats (liters/h) 335.8 0 0 0 1612.0 0

Surplus electricity 196.14 276.52 200.87 199.57 117.44 289.57

(MWh)

17 Global efficiency and net productivity per hectare

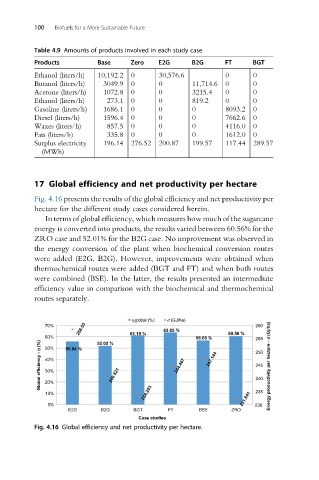

Fig. 4.16 presents the results of the global efficiency and net productivity per

hectare for the different study cases considered herein.

In terms of global efficiency, which measures how much of the sugarcane

energy is converted into products, the results varied between 60.56% for the

ZRO case and 52.01% for the B2G case. No improvement was observed in

the energy conversion of the plant when biochemical conversion routes

were added (E2G, B2G). However, improvements were obtained when

thermochemical routes were added (BGT and FT) and when both routes

were combined (BSE). In the latter, the results presented an intermediate

efficiency value in comparison with the biochemical and thermochemical

routes separately.

h global (%) s (GJ/ha)

258.53 63.85 %

70% 260

60% 55.84 % 52.02 % 61.19 % 56.65 % 60.56 % 255

Global efficiency - h (%) 40% 240.821 244.467 247.144 250 Energy productivity per hectare - s (Gj/ha)

50%

245

30%

240

20%

10% 234.253 231.841 235

0% 230

E2G B2G BGT FT BSE ZRO

Case studies

Fig. 4.16 Global efficiency and net productivity per hectare.