Page 112 - Biofuels for a More Sustainable Future

P. 112

Indicators for sustainability assessment 99

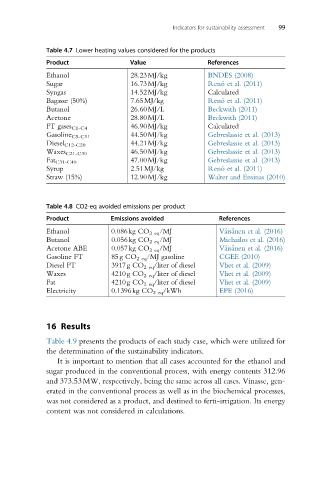

Table 4.7 Lower heating values considered for the products

Product Value References

Ethanol 28.23MJ/kg BNDES (2008)

Sugar 16.73MJ/kg Reno ´ et al. (2011)

Syngas 14.52MJ/kg Calculated

Bagasse (50%) 7.65MJ/kg Reno ´ et al. (2011)

Butanol 26.60MJ/L Beckwith (2011)

Acetone 28.80MJ/L Beckwith (2011)

46.90MJ/kg Calculated

FT gases C1-C4

44.50MJ/kg Gebreslassie et al. (2013)

Gasoline C5-C11

Diesel C12-C20 44.21MJ/kg Gebreslassie et al. (2013)

46.50MJ/kg Gebreslassie et al. (2013)

Waxes C21-C30

47.00MJ/kg Gebreslassie et al. (2013)

Fat C31-C40

Syrup 2.51MJ/kg Reno ´ et al. (2011)

Straw (15%) 12.90MJ/kg Walter and Ensinas (2010)

Table 4.8 CO2-eq avoided emissions per product

Product Emissions avoided References

Ethanol 0.086kg CO 2eq /MJ V€ais€anen et al. (2016)

Butanol 0.056kg CO 2eq /MJ Michailos et al. (2016)

Acetone ABE 0.057kg CO 2eq /MJ V€ais€anen et al. (2016)

Gasoline FT 85g CO 2eq /MJ gasoline CGEE (2010)

Diesel FT 3917g CO 2eq /liter of diesel Vliet et al. (2009)

Waxes 4210g CO 2eq /liter of diesel Vliet et al. (2009)

Fat 4210g CO 2eq /liter of diesel Vliet et al. (2009)

Electricity 0.1396kg CO 2eq /kWh EPE (2016)

16 Results

Table 4.9 presents the products of each study case, which were utilized for

the determination of the sustainability indicators.

It is important to mention that all cases accounted for the ethanol and

sugar produced in the conventional process, with energy contents 312.96

and 373.53MW, respectively, being the same across all cases. Vinasse, gen-

erated in the conventional process as well as in the biochemical processes,

was not considered as a product, and destined to ferti-irrigation. Its energy

content was not considered in calculations.