Page 104 - Biofuels for a More Sustainable Future

P. 104

Indicators for sustainability assessment 93

10 Pretreatment of bagasse

The pretreatment step comprehends drying, roasting, and crushing, and pre-

pares biomass for the fluidized bed gasification process, providing adequate

granulometry and humidity, and improving energy density.

11 Production and cleaning of syngas

Production and cleaning of syngas encompasses the gasification steps in flu-

idized bed and cleaning of the obtained gas. Gasification is a complex pro-

cess, sensitive to several factors such as gasification temperature, equivalence

ratio, biomass granulometry, and demands oxygen with elevated purity.

Therefore the production step of syngas includes a unit for air separation,

which produces the oxidizing agent for gasification. The quality of syngas

limits its utilization in other processes, and therefore cleaning has the objec-

tive of removing unwanted compounds, enabling its utilization in BIG-

GTCC cycles and in FT synthesis.

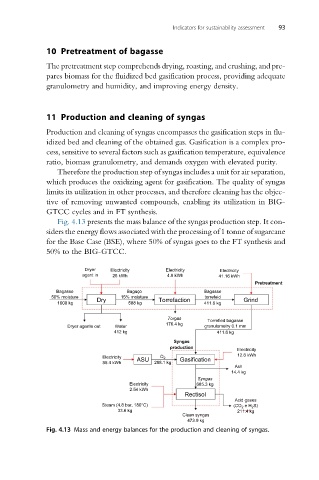

Fig. 4.13 presents the mass balance of the syngas production step. It con-

siders the energy flows associated with the processing of 1 tonne of sugarcane

for the Base Case (BSE), where 50% of syngas goes to the FT synthesis and

50% to the BIG-GTCC.

Dryer Electricity Electricity Electricity

agent in 26 kWh 4.9 kWh 41.16 kWh

Pretreatment

Bagasse Bagaço Bagasse

50% moisture Dry 15% moisture Torrefaction torrefeid Grind

1000 kg 588 kg 411.6 kg

Torgas Torrefied bagasse

176.4 kg

Dryer agente out Water granulometry 0.1 mm

412 kg 411.6 kg

Syngas

production

Electricity

12.8 kWh

Electricity ASU O 2 Gasification

86.4 kWh 288.1 kg

Ash

14.4 kg

Syngas

Electricity 685.3 kg

2.54 kWh

Rectisol

Acid gases

Steam (4.8 bar, 180°C) (CO 2 e H 2 S)

33.6 kg 211.4 kg

Clean syngas

473.9 kg

Fig. 4.13 Mass and energy balances for the production and cleaning of syngas.