Page 30 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 30

Chapter | 1 Introduction 9

Water

Sugar, corn

feedstock

Ethanol

Sugar

fermented to

alcoholic

Yeast

“beer”

Distillation

Liquid beer

Residues Animal feed

(A)

Enzymes

Acid and Water and Water

Cellulosic Feedstock

Acids break Hemicellulose

biomass into syrup for Cellulosic

base sugars pentose ethanol

and fibers fermentation

Distillation

Cellulose and lignin fibers

Cellulose Liquid beer

Enzymes solids for

and water hydrolysis and

ethanol Boiler to

fermentation generate

Lignin steam for

(B) process

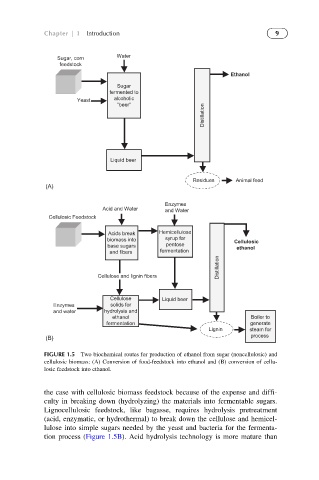

FIGURE 1.5 Two biochemical routes for production of ethanol from sugar (noncellulosic) and

cellulosic biomass: (A) Conversion of food-feedstock into ethanol and (B) conversion of cellu-

losic feedstock into ethanol.

the case with cellulosic biomass feedstock because of the expense and diffi-

culty in breaking down (hydrolyzing) the materials into fermentable sugars.

Lignocellulosic feedstock, like bagasse, requires hydrolysis pretreatment

(acid, enzymatic, or hydrothermal) to break down the cellulose and hemicel-

lulose into simple sugars needed by the yeast and bacteria for the fermenta-

tion process (Figure 1.5B). Acid hydrolysis technology is more mature than