Page 31 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 31

10 Biomass Gasification, Pyrolysis, and Torrefaction

enzymatic hydrolysis technology though the latter could have a significant

cost advantage.

1.2.2 Thermochemical Conversion

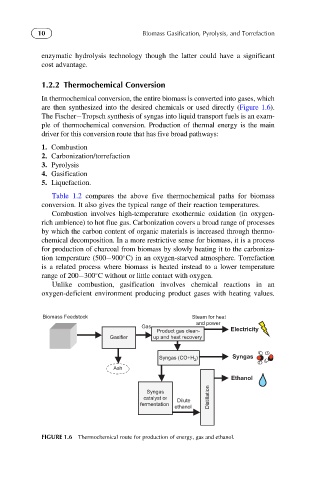

In thermochemical conversion, the entire biomass is converted into gases, which

are then synthesized into the desired chemicals or used directly (Figure 1.6).

The Fischer Tropsch synthesis of syngas into liquid transport fuels is an exam-

ple of thermochemical conversion. Production of thermal energy is the main

driver for this conversion route that has five broad pathways:

1. Combustion

2. Carbonization/torrefaction

3. Pyrolysis

4. Gasification

5. Liquefaction.

Table 1.2 compares the above five thermochemical paths for biomass

conversion. It also gives the typical range of their reaction temperatures.

Combustion involves high-temperature exothermic oxidation (in oxygen-

rich ambience) to hot flue gas. Carbonization covers a broad range of processes

by which the carbon content of organic materials is increased through thermo-

chemical decomposition. In a more restrictive sense for biomass, it is a process

for production of charcoal from biomass by slowly heating it to the carboniza-

tion temperature (500 900 C) in an oxygen-starved atmosphere. Torrefaction

is a related process where biomass is heated instead to a lower temperature

range of 200 300 C without or little contact with oxygen.

Unlike combustion, gasification involves chemical reactions in an

oxygen-deficient environment producing product gases with heating values.

Biomass Feedstock Steam for heat

and power

Gas

Product gas clean- Electricity

Gasifier up and heat recovery

Syngas (CO+H ) Syngas

2

Ash

Ethanol

Syngas

catalyst or Dilute Distillation

fermentation

ethanol

FIGURE 1.6 Thermochemical route for production of energy, gas and ethanol.