Page 341 - Biomedical Engineering and Design Handbook Volume 1, Fundamentals

P. 341

318 BIOMATERIALS

stress is applied at t , a constant deformation with time, and then returns to its original length

i

when the load is removed. Therefore the elastic solid does not creep. The viscous (dashpot)

model deforms continuously (creeps) from t to t and remains permanently deformed after removal

f

i

of load.

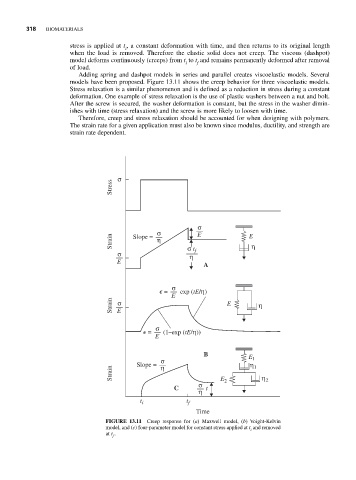

Adding spring and dashpot models in series and parallel creates viscoelastic models. Several

models have been proposed. Figure 13.11 shows the creep behavior for three viscoelastic models.

Stress relaxation is a similar phenomenon and is defined as a reduction in stress during a constant

deformation. One example of stress relaxation is the use of plastic washers between a nut and bolt.

After the screw is secured, the washer deformation is constant, but the stress in the washer dimin-

ishes with time (stress relaxation) and the screw is more likely to loosen with time.

Therefore, creep and stress relaxation should be accounted for when designing with polymers.

The strain rate for a given application must also be known since modulus, ductility, and strength are

strain rate dependent.

σ

Stress

σ

σ E E

Strain Slope = η η

σ σ t f

η

E

A

σ

= exp (tE/η)

E

Strain E E η

σ

σ

= (1–exp (tE/η))

E

B

σ E 1

Slope = η η 1

Strain E 2 η 2

C σ t

η

t i t f

Time

FIGURE 13.11 Creep response for (a) Maxwell model, (b) Voight-Kelvin

model, and (c) four-parameter model for constant stress applied at t and removed

i

at t .

f