Page 244 - Biomimetics : Biologically Inspired Technologies

P. 244

Bar-Cohen : Biomimetics: Biologically Inspired Technologies DK3163_c008 Final Proof page 230 21.9.2005 3:07am

230 Biomimetics: Biologically Inspired Technologies

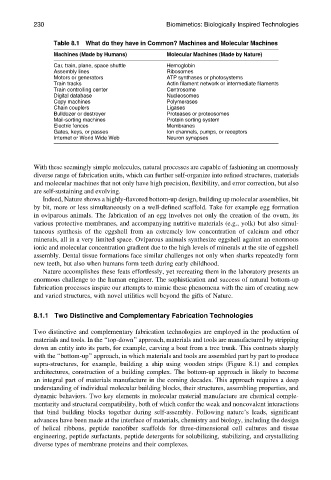

Table 8.1 What do they have in Common? Machines and Molecular Machines

Machines (Made by Humans) Molecular Machines (Made by Nature)

Car, train, plane, space shuttle Hemoglobin

Assembly lines Ribosomes

Motors or generators ATP synthases or photosystems

Train tracks Actin filament network or intermediate filaments

Train controlling center Centrosome

Digital database Nucleosomes

Copy machines Polymerases

Chain couplers Ligases

Bulldozer or destroyer Proteases or proteosomes

Mail-sorting machines Protein sorting system

Electric fences Membranes

Gates, keys, or passes Ion channels, pumps, or receptors

Internet or World Wide Web Neuron synapses

With these seemingly simple molecules, natural processes are capable of fashioning an enormously

diverse range of fabrication units, which can further self-organize into refined structures, materials

and molecular machines that not only have high precision, flexibility, and error correction, but also

are self-sustaining and evolving.

Indeed, Nature shows a highly-flavored bottom-up design, building up molecular assemblies, bit

by bit, more or less simultaneously on a well-defined scaffold. Take for example egg formation

in oviparous animals. The fabrication of an egg involves not only the creation of the ovum, its

various protective membranes, and accompanying nutritive materials (e.g., yolk) but also simul-

taneous synthesis of the eggshell from an extremely low concentration of calcium and other

minerals, all in a very limited space. Oviparous animals synthesize eggshell against an enormous

ionic and molecular concentration gradient due to the high levels of minerals at the site of eggshell

assembly. Dental tissue formations face similar challenges not only when sharks repeatedly form

new teeth, but also when humans form teeth during early childhood.

Nature accomplishes these feats effortlessly, yet recreating them in the laboratory presents an

enormous challenge to the human engineer. The sophistication and success of natural bottom-up

fabrication processes inspire our attempts to mimic these phenomena with the aim of creating new

and varied structures, with novel utilities well beyond the gifts of Nature.

8.1.1 Two Distinctive and Complementary Fabrication Technologies

Two distinctive and complementary fabrication technologies are employed in the production of

materials and tools. In the ‘‘top-down’’ approach, materials and tools are manufactured by stripping

down an entity into its parts, for example, carving a boat from a tree trunk. This contrasts sharply

with the ‘‘bottom-up’’ approach, in which materials and tools are assembled part by part to produce

supra-structures, for example, building a ship using wooden strips (Figure 8.1) and complex

architectures, construction of a building complex. The bottom-up approach is likely to become

an integral part of materials manufacture in the coming decades. This approach requires a deep

understanding of individual molecular building blocks, their structures, assembling properties, and

dynamic behaviors. Two key elements in molecular material manufacture are chemical comple-

mentarity and structural compatibility, both of which confer the weak and noncovalent interactions

that bind building blocks together during self-assembly. Following nature’s leads, significant

advances have been made at the interface of materials, chemistry and biology, including the design

of helical ribbons, peptide nanofiber scaffolds for three-dimensional cell cultures and tissue

engineering, peptide surfactants, peptide detergents for solubilizing, stabilizing, and crystallizing

diverse types of membrane proteins and their complexes.