Page 95 - Biorefinery 2030 Future Prospects for the Bioeconomy (2015)

P. 95

3 The Bazancourt-Pomacle Biorefinery: An On-Going Success Story? 63

BIODEMO 55 with a capacity of 2000 tonnes per year. With this unit, BIOAMBER

successfully tested its technology and finalised the process book with a view to the

sale of licences.

This type of production was the first of its kind in the world. It could revolution-

ise the markets for bio-based products. It has already provoked a wave of enthusi-

asm, enabling large funding sums to be raised (c.f. Box 2.7).

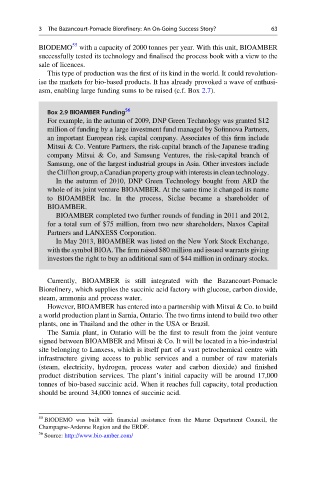

Box 2.9 BIOAMBER Funding 56

For example, in the autumn of 2009, DNP Green Technology was granted $12

million of funding by a large investment fund managed by Sofinnova Partners,

an important European risk capital company. Associates of this firm include

Mitsui & Co. Venture Partners, the risk-capital branch of the Japanese trading

company Mitsui & Co, and Samsung Ventures, the risk-capital branch of

Samsung, one of the largest industrial groups in Asia. Other investors include

the Cliffton group, a Canadian property group with interests in clean technology.

In the autumn of 2010, DNP Green Technology bought from ARD the

whole of its joint venture BIOAMBER. At the same time it changed its name

to BIOAMBER Inc. In the process, Siclae became a shareholder of

BIOAMBER.

BIOAMBER completed two further rounds of funding in 2011 and 2012,

for a total sum of $75 million, from two new shareholders, Naxos Capital

Partners and LANXESS Corporation.

In May 2013, BIOAMBER was listed on the New York Stock Exchange,

with the symbol BIOA. The firm raised $80 million and issued warrants giving

investors the right to buy an additional sum of $44 million in ordinary stocks.

Currently, BIOAMBER is still integrated with the Bazancourt-Pomacle

Biorefinery, which supplies the succinic acid factory with glucose, carbon dioxide,

steam, ammonia and process water.

However, BIOAMBER has entered into a partnership with Mitsui & Co. to build

a world production plant in Sarnia, Ontario. The two firms intend to build two other

plants, one in Thailand and the other in the USA or Brazil.

The Sarnia plant, in Ontario will be the first to result from the joint venture

signed between BIOAMBER and Mitsui & Co. It will be located in a bio-industrial

site belonging to Lanxess, which is itself part of a vast petrochemical centre with

infrastructure giving access to public services and a number of raw materials

(steam, electricity, hydrogen, process water and carbon dioxide) and finished

product distribution services. The plant’s initial capacity will be around 17,000

tonnes of bio-based succinic acid. When it reaches full capacity, total production

should be around 34,000 tonnes of succinic acid.

55

BIODEMO was built with financial assistance from the Marne Department Council, the

Champagne-Ardenne Region and the ERDF.

56

Source: http://www.bio-amber.com/