Page 170 - Boiler_Operators_Handbook,_Second_Edition

P. 170

Refrigeration & AC 155

compressor cylinder through an intake valve or valves. the pressure of the gas at the outlet to overcome the force

My best description for the valves of a refrigeration of the spring on the valve and the discharge valve opens.

compressor is they look like popsicle sticks. They are For the remainder of the upward stroke gas is pushed

guided within the casting of a cylinder head and are ei- out of the cylinder into the discharge piping. The vol-

ther a spring themselves or guided by springs that gen- ume of gas delivered with each rotation of the shaft isn’t

tly push them toward the seat. The flow of gas pushes a function of the cylinder displacement because the gas

the valve away from the opening and, when flow stops, has to expand and compress. The amount of gas pushed

the spring force pushes the valve back onto its seat. As through the compressor is considerably less than the

the piston approaches the bottom of its stroke it slows volume displaced by the piston in the cylinder.

down then reverses due to the rotary motion of the pis- Small compressors are started under load. To allow

ton connecting rod at the crankshaft. Then, as the pis- larger compressors to get up to speed before starting to

ton rises in the cylinder, reducing the volume, the gas is pump refrigerant unloading systems are used. Unload-

compressed until it is at a pressure slightly higher than ing a cylinder is accomplished with a pin that pushes

up against each suction valve to hold it open. The pin

is connected to a small cylinder containing a spring as

shown in Figure 5-8. When the compressor is shut down

the springs push the pins up to hold the valves open. Af-

ter the compressor gets up to speed the oil pump builds

up pressure in the oil passages of the compressor and

the small unloader cylinders to force the pins down and

allow the suction valves to operate. You can tell when

the unloaders operate because there will be a significant

difference in the sound of the compressor as it comes up

to speed. The unloaders allow a compressor to be pow-

ered by a standard duty motor instead of a high torque

motor. Many modern compressors use a solenoid and

spring to control the pins electronically.

In addition to reducing startup torque unloaders

allow multiple cylinder compressors to handle varying

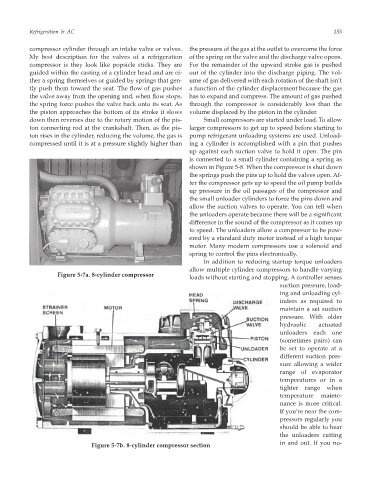

Figure 5-7a. 8-cylinder compressor

loads without starting and stopping. A controller senses

suction pressure, load-

ing and unloading cyl-

inders as required to

maintain a set suction

pressure. With older

hydraulic actuated

unloaders each one

(sometimes pairs) can

be set to operate at a

different suction pres-

sure allowing a wider

range of evaporator

temperatures or in a

tighter range when

temperature mainte-

nance is more critical.

If you’re near the com-

pressors regularly you

should be able to hear

the unloaders cutting

in and out. If you no-

Figure 5-7b. 8-cylinder compressor section