Page 173 - Boiler_Operators_Handbook,_Second_Edition

P. 173

158 Boiler Operator’s Handbook

Figure 5-13. Screw compressor

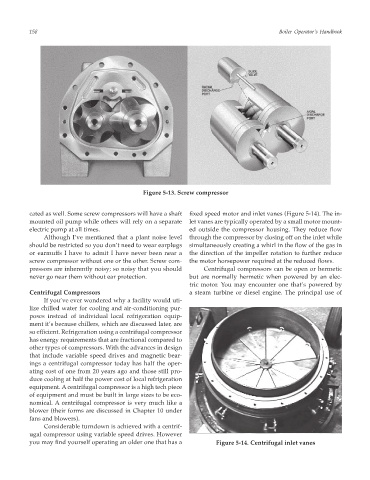

cated as well. Some screw compressors will have a shaft fixed speed motor and inlet vanes (Figure 5-14). The in-

mounted oil pump while others will rely on a separate let vanes are typically operated by a small motor mount-

electric pump at all times. ed outside the compressor housing. They reduce flow

Although I’ve mentioned that a plant noise level through the compressor by closing off on the inlet while

should be restricted so you don’t need to wear earplugs simultaneously creating a whirl in the flow of the gas in

or earmuffs I have to admit I have never been near a the direction of the impeller rotation to further reduce

screw compressor without one or the other. Screw com- the motor horsepower required at the reduced flows.

pressors are inherently noisy; so noisy that you should Centrifugal compressors can be open or hermetic

never go near them without ear protection. but are normally hermetic when powered by an elec-

tric motor. You may encounter one that’s powered by

Centrifugal Compressors a steam turbine or diesel engine. The principal use of

If you’ve ever wondered why a facility would uti-

lize chilled water for cooling and air-conditioning pur-

poses instead of individual local refrigeration equip-

ment it’s because chillers, which are discussed later, are

so efficient. Refrigeration using a centrifugal compressor

has energy requirements that are fractional compared to

other types of compressors. With the advances in design

that include variable speed drives and magnetic bear-

ings a centrifugal compressor today has half the oper-

ating cost of one from 20 years ago and those still pro-

duce cooling at half the power cost of local refrigeration

equipment. A centrifugal compressor is a high tech piece

of equipment and must be built in large sizes to be eco-

nomical. A centrifugal compressor is very much like a

blower (their forms are discussed in Chapter 10 under

fans and blowers).

Considerable turndown is achieved with a centrif-

ugal compressor using variable speed drives. However

you may find yourself operating an older one that has a Figure 5-14. Centrifugal inlet vanes