Page 175 - Boiler_Operators_Handbook,_Second_Edition

P. 175

160 Boiler Operator’s Handbook

temperature one would expect to encounter. Most of but it would also reduce the pressure differential across

these are designed to condense the refrigerant using air the throttling device and restrict flow of the refrigerant

at 120°F. The auto manufacturers cannot take a chance for inadequate cooling. Simply shutting down the fan(s)

making vehicles that would not, on some day, pay a can reduce heat transfer to raise condenser pressure to

visit to the deep South or, as Sue and I did last winter, an acceptable value but air cooled condensers in cold-

visit Death Valley. Heat transfer between metal and air er climates can also include dampers that can control

is poor compared to metal to condensing vapor so you airflow over the fins and coils to maintain a condenser

will find most air cooled condensers have fins in tight pressure.

contact with the condenser tubing to increase the surface

for heat transfer between the metal and air. Provisions Condensing Units

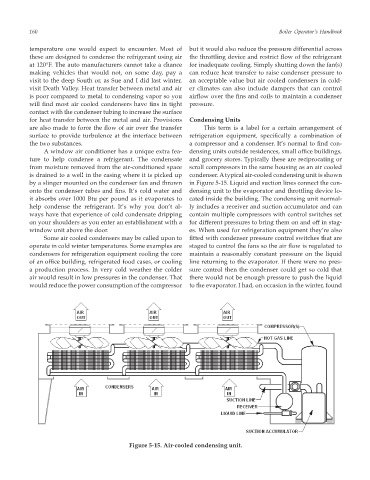

are also made to force the flow of air over the transfer This term is a label for a certain arrangement of

surface to provide turbulence at the interface between refrigeration equipment, specifically a combination of

the two substances. a compressor and a condenser. It’s normal to find con-

A window air conditioner has a unique extra fea- densing units outside residences, small office buildings,

ture to help condense a refrigerant. The condensate and grocery stores. Typically these are reciprocating or

from moisture removed from the air-conditioned space scroll compressors in the same housing as an air cooled

is drained to a well in the casing where it is picked up condenser. A typical air-cooled condensing unit is shown

by a slinger mounted on the condenser fan and thrown in Figure 5-15. Liquid and suction lines connect the con-

onto the condenser tubes and fins. It’s cold water and densing unit to the evaporator and throttling device lo-

it absorbs over 1000 Btu per pound as it evaporates to cated inside the building. The condensing unit normal-

help condense the refrigerant. It’s why you don’t al- ly includes a receiver and suction accumulator and can

ways have that experience of cold condensate dripping contain multiple compressors with control switches set

on your shoulders as you enter an establishment with a for different pressures to bring them on and off in stag-

window unit above the door. es. When used for refrigeration equipment they’re also

Some air cooled condensers may be called upon to fitted with condenser pressure control switches that are

operate in cold winter temperatures. Some examples are staged to control the fans so the air flow is regulated to

condensers for refrigeration equipment cooling the core maintain a reasonably constant pressure on the liquid

of an office building, refrigerated food cases, or cooling line returning to the evaporator. If there were no pres-

a production process. In very cold weather the colder sure control then the condenser could get so cold that

air would result in low pressures in the condenser. That there would not be enough pressure to push the liquid

would reduce the power consumption of the compressor to the evaporator. I had, on occasion in the winter, found

Figure 5-15. Air-cooled condensing unit.