Page 180 - Boiler_Operators_Handbook,_Second_Edition

P. 180

Refrigeration & AC 165

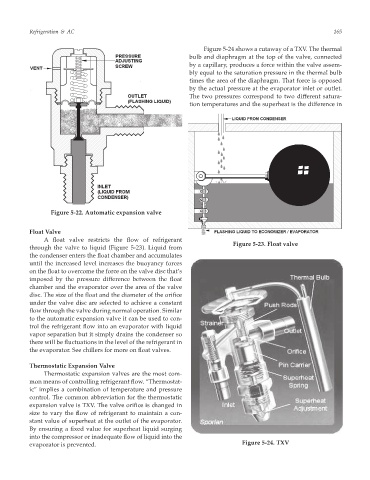

Figure 5-24 shows a cutaway of a TXV. The thermal

bulb and diaphragm at the top of the valve, connected

by a capillary, produces a force within the valve assem-

bly equal to the saturation pressure in the thermal bulb

times the area of the diaphragm. That force is opposed

by the actual pressure at the evaporator inlet or outlet.

The two pressures correspond to two different satura-

tion temperatures and the superheat is the difference in

Figure 5-22. Automatic expansion valve

Float Valve

A float valve restricts the flow of refrigerant

Figure 5-23. Float valve

through the valve to liquid (Figure 5-23). Liquid from

the condenser enters the float chamber and accumulates

until the increased level increases the buoyancy forces

on the float to overcome the force on the valve disc that’s

imposed by the pressure difference between the float

chamber and the evaporator over the area of the valve

disc. The size of the float and the diameter of the orifice

under the valve disc are selected to achieve a constant

flow through the valve during normal operation. Similar

to the automatic expansion valve it can be used to con-

trol the refrigerant flow into an evaporator with liquid

vapor separation but it simply drains the condenser so

there will be fluctuations in the level of the refrigerant in

the evaporator. See chillers for more on float valves.

Thermostatic Expansion Valve

Thermostatic expansion valves are the most com-

mon means of controlling refrigerant flow. “Thermostat-

ic” implies a combination of temperature and pressure

control. The common abbreviation for the thermostatic

expansion valve is TXV. The valve orifice is changed in

size to vary the flow of refrigerant to maintain a con-

stant value of superheat at the outlet of the evaporator.

By ensuring a fixed value for superheat liquid surging

into the compressor or inadequate flow of liquid into the

evaporator is prevented. Figure 5-24. TXV