Page 184 - Boiler_Operators_Handbook,_Second_Edition

P. 184

Refrigeration & AC 169

a vacuum which might result in ambient air containing

moisture entering the system should it be leaking. I be-

lieve I said elsewhere in this book that a system can be

tight under pressure but leak under a vacuum because a

piece of rust or a defect in construction can produce the

equivalent of a check valve at the leak site.

If you are pumping down the system for mainte-

nance, that requires opening the system, a separate inde-

pendent vacuum pump should be used to recover the re-

maining refrigerant and evacuate the system. A recovery

system should also be used to remove refrigerant from a

compressor, condenser, or receiver before opening them

for inspection or maintenance of the refrigerant side of

the system. Recall that evacuating a system for mainte-

nance and opening a system require you be licensed by

EPA to handle refrigerants.

Load Control Valves

When a refrigeration system serves multiple

loads control valves are installed in the liquid lines

Figure 5-28. Isolating valve with bellows seal to start and stop the flow of liquid refrigerant to each

load. These are normally solenoid controlled valves

actuated by a thermostat. Aboard ship we had evap-

orators in many spaces. Some were used all the time

such as ships stores, food freezers, refrigerators, and

other equipment in the galley. Then each deck in each

hold could have coils for refrigeration or freezing of the

cargo in that space. The Santa Louisa, my first ship as

a licensed ship’s engineer carried bananas back from

South America and we refrigerated all the holds that

contained those bananas. Facilities ashore such as food

distribution centers, large supermarkets, and the like

can have central refrigeration condensing units serving

freezers and refrigerated boxes.

Defrost Valves and Lines

In order to defrost evaporators used in freezing

applications some systems include a defrost valve and

piping or tubing that transfers refrigerant from the hot

gas lines to the inlet of the evaporator to melt ice accu-

mulating on the evaporator. A defrost valve is identical

to a load control valve with the exception of size (larger

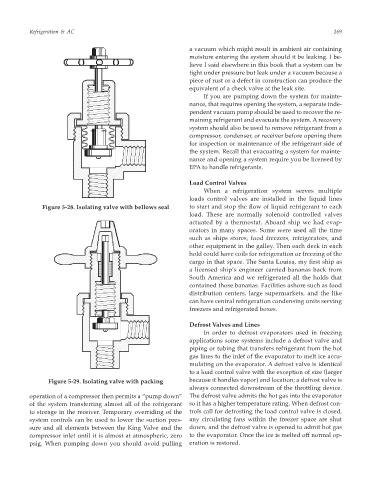

Figure 5-29. Isolating valve with packing because it handles vapor) and location; a defrost valve is

always connected downstream of the throttling device.

operation of a compressor then permits a “pump down” The defrost valve admits the hot gas into the evaporator

of the system transferring almost all of the refrigerant so it has a higher temperature rating. When defrost con-

to storage in the receiver. Temporary overriding of the trols call for defrosting the load control valve is closed,

system controls can be used to lower the suction pres- any circulating fans within the freezer space are shut

sure and all elements between the King Valve and the down, and the defrost valve is opened to admit hot gas

compressor inlet until it is almost at atmospheric, zero to the evaporator. Once the ice is melted off normal op-

psig. When pumping down you should avoid pulling eration is restored.