Page 181 - Boiler_Operators_Handbook,_Second_Edition

P. 181

166 Boiler Operator’s Handbook

those two. The difference between the two forces on the

diaphragm is opposed by a spring. When the difference

increases, due to an increase in superheat, the spring is

compressed to open the valve further and increase the

flow of liquid into the evaporator. Conversely, a de-

crease in superheat will result in the valve closing down

to reduce liquid flow.

In some applications where the pressure drop of

the liquid and gas flowing through the evaporator is

low the evaporator pressure is sensed only at the valve

outlet. For most installations however, the lower dia-

phragm chamber is connected to the evaporator outlet

with an external sensing line, commonly referred to as

an equalizing tube, which is shown in Figure 5-25. The

TXV outlet pressure sensing connection is a small orifice

in the valve body and the flow through it is dumped off

so fast through the sensing line to the evaporator outlet

that the pressure on the bottom of the diaphragm is very Figure 5-25. TXV installation

close to the evaporator outlet pressure. This installation

change the setting of the superheat. This should be a “set

ensures the TXV is controlling by the actual superheat at

and forget” adjustment. If you have reason to believe

the outlet of the evaporator.

that the valve is not working properly there are many

The TXV has a strainer at the inlet that is accessible

things to check before adjusting the superheat setting.

for cleaning. It cannot be removed for cleaning without

Understanding the operation of the valve should aid

removing the refrigerant from the system. Periodic clean-

you in determining what the problems might be. A com-

ing is not required; the principal purpose of the strainer is

mon problem is vibration loosening the mounting of the

to catch droplets of solder and contaminants in the liquid

thermal bulb.

line upon startup of the system or products carried down

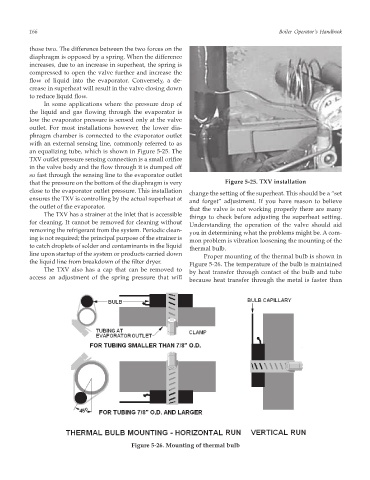

Proper mounting of the thermal bulb is shown in

the liquid line from breakdown of the filter dryer.

Figure 5-26. The temperature of the bulb is maintained

The TXV also has a cap that can be removed to

by heat transfer through contact of the bulb and tube

access an adjustment of the spring pressure that will

because heat transfer through the metal is faster than

Figure 5-26. Mounting of thermal bulb