Page 177 - Boiler_Operators_Handbook,_Second_Edition

P. 177

162 Boiler Operator’s Handbook

tubes of the condensers were made of

high-quality brass and bronze. Sacri-

ficial magnesium anodes electrically

connected to the condensers provided

additional protection against corrosion.

Plants using seawater or brackish water

would be constructed similarly but, if

large, use electrically powered cathodic

protection for corrosion. Growth of al-

gae, bacteria, bivalves, etc., on the heat

transfer surfaces are also concerns for

those condensers. The pressure drop

through and temperature differential of

these condensers has to be monitored

closely to identify conditions of organic

growth hindering heat transfer.

Well water will have the highest

dissolved solids content of any supply

Figure 5-16. Evaporative condenser

of condenser cooling water. Normally,

when the well water is not circulated,

it will not present a problem. However, I have seen

sources that will form scale on heat transfer surfaces

after a temperature rise of only a few degrees. Regu-

lar sampling and testing of the TDS of the well water

should allow you to detect conditions that could con-

tribute to scaling. The important thing to do with high

solids water is to maintain a minimum rate of water

flow through the condenser and avoid concentrating

solids content by blowdown or other means.

Water drawn from rivers, lakes and reservoirs will

normally have lower dissolved solids content but can

have a considerably higher organic materials content.

Water circulating through a condenser and the cooling

tower will also pick up organic materials. When those

waters are used in condensers they will require regular

cleanings to remove the organics, algae, and bacterial

growth. Monitoring of the pressure and temperature

differentials under these conditions is imperative.

Condenser Pressure Control Valves

To maintain the pressure in a water cooled con-

denser above a minimum value self-contained pressure

control valves modulate the flow of the water leaving

the condenser. A capillary containing a refrigerant

charge is connected to a bellows in the valve assembly

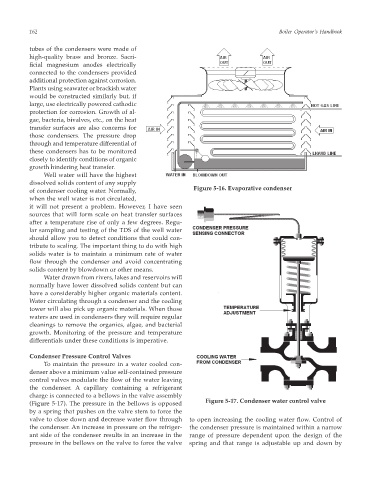

Figure 5-17. Condenser water control valve

(Figure 5-17). The pressure in the bellows is opposed

by a spring that pushes on the valve stem to force the

valve to close down and decrease water flow through to open increasing the cooling water flow. Control of

the condenser. An increase in pressure on the refriger- the condenser pressure is maintained within a narrow

ant side of the condenser results in an increase in the range of pressure dependent upon the design of the

pressure in the bellows on the valve to force the valve spring and that range is adjustable up and down by