Page 171 - Boiler_Operators_Handbook,_Second_Edition

P. 171

156 Boiler Operator’s Handbook

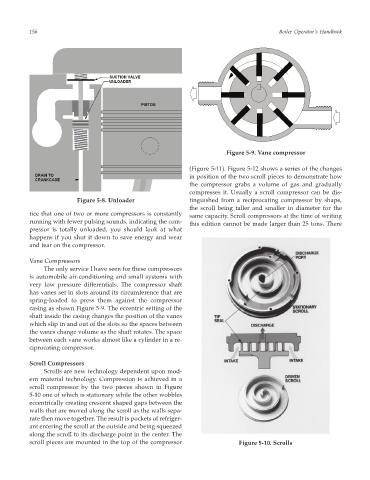

Figure 5-9. Vane compressor

(Figure 5-11). Figure 5-12 shows a series of the changes

in position of the two scroll pieces to demonstrate how

the compressor grabs a volume of gas and gradually

compresses it. Usually a scroll compressor can be dis-

Figure 5-8. Unloader tinguished from a reciprocating compressor by shape,

the scroll being taller and smaller in diameter for the

tice that one of two or more compressors is constantly

same capacity. Scroll compressors at the time of writing

running with fewer pulsing sounds, indicating the com-

this edition cannot be made larger than 25 tons. There

pressor is totally unloaded, you should look at what

happens if you shut it down to save energy and wear

and tear on the compressor.

Vane Compressors

The only service I have seen for these compressors

is automobile air-conditioning and small systems with

very low pressure differentials. The compressor shaft

has vanes set in slots around its circumference that are

spring-loaded to press them against the compressor

casing as shown Figure 5-9. The eccentric setting of the

shaft inside the casing changes the position of the vanes

which slip in and out of the slots so the spaces between

the vanes change volume as the shaft rotates. The space

between each vane works almost like a cylinder in a re-

ciprocating compressor.

Scroll Compressors

Scrolls are new technology dependent upon mod-

ern material technology. Compression is achieved in a

scroll compressor by the two pieces shown in Figure

5-10 one of which is stationary while the other wobbles

eccentrically creating crescent shaped gaps between the

walls that are moved along the scroll as the walls sepa-

rate then move together. The result is pockets of refriger-

ant entering the scroll at the outside and being squeezed

along the scroll to its discharge point in the center. The

scroll pieces are mounted in the top of the compressor Figure 5-10. Scrolls