Page 337 - Boiler_Operators_Handbook,_Second_Edition

P. 337

322 Boiler Operator’s Handbook

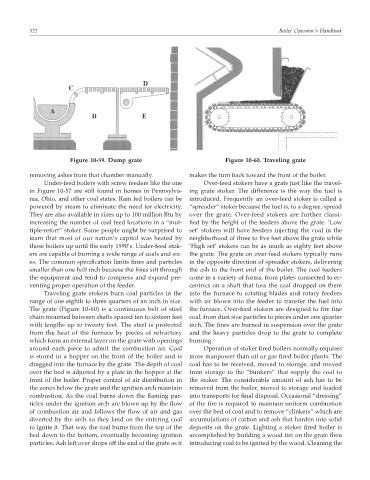

Figure 10-59. Dump grate Figure 10-60. Traveling grate

removing ashes from that chamber manually. makes the turn back toward the front of the boiler.

Under-feed boilers with screw feeders like the one Over-feed stokers have a grate just like the travel-

in Figure 10-57 are still found in homes in Pennsylva- ing grate stoker. The difference is the way the fuel is

nia, Ohio, and other coal states. Ram fed boilers can be introduced. Frequently an over-feed stoker is called a

powered by steam to eliminate the need for electricity. “spreader” stoker because the fuel is, to a degree, spread

They are also available in sizes up to 100 million Btu by over the grate. Over-feed stokers are further classi-

increasing the number of coal feed locations in a “mul- fied by the height of the feeders above the grate. ‘Low

tiple-retort” stoker. Some people might be surprised to set’ stokers will have feeders injecting the coal in the

learn that most of our nation’s capitol was heated by neighborhood of three to five feet above the grate while

those boilers up until the early 1990’s. Under-feed stok- ‘High set’ stokers can be as much as eighty feet above

ers are capable of burning a wide range of coals and siz- the grate. The grate on over-feed stokers typically runs

es. The common specification limits fines and particles in the opposite direction of spreader stokers, delivering

smaller than one half inch because the fines sift through the ash to the front end of the boiler. The coal feeders

the equipment and tend to compress and expand pre- come in a variety of forms, from plates connected to ec-

venting proper operation of the feeder. centrics on a shaft that toss the coal dropped on them

Traveling grate stokers burn coal particles in the into the furnace to rotating blades and rotary feeders

range of one eighth to three quarters of an inch in size. with air blown into the feeder to transfer the fuel into

The grate (Figure 10-60) is a continuous belt of steel the furnace. Over-feed stokers are designed to fire fine

chain mounted between shafts spaced ten to sixteen feet coal, from dust size particles to pieces under one quarter

with lengths up to twenty feet. The steel is protected inch. The fines are burned in suspension over the grate

from the heat of the furnace by pieces of refractory and the heavy particles drop to the grate to complete

which form an external layer on the grate with openings burning.

around each piece to admit the combustion air. Coal Operation of stoker fired boilers normally requires

is stored in a hopper on the front of the boiler and is more manpower than oil or gas fired boiler plants. The

dragged into the furnace by the grate. The depth of coal coal has to be received, moved to storage, and moved

over the bed is adjusted by a plate in the hopper at the from storage to the “bunkers” that supply the coal to

front of the boiler. Proper control of air distribution in the stoker. The considerable amount of ash has to be

the zones below the grate and the ignition arch maintain removed from the boiler, moved to storage and loaded

combustion. As the coal burns down the flaming par- into transports for final disposal. Occasional “dressing”

ticles under the ignition arch are blown up by the flow of the fire is required to maintain uniform combustion

of combustion air and follows the flow of air and gas over the bed of coal and to remove “clinkers” which are

diverted by the arch so they land on the entering coal accumulations of carbon and ash that harden into solid

to ignite it. That way the coal burns from the top of the deposits on the grate. Lighting a stoker fired boiler is

bed down to the bottom, eventually becoming ignition accomplished by building a wood fire on the grate then

particles. Ash left over drops off the end of the grate as it introducing coal to be ignited by the wood. Cleaning the