Page 334 - Boiler_Operators_Handbook,_Second_Edition

P. 334

Plants and Equipment 319

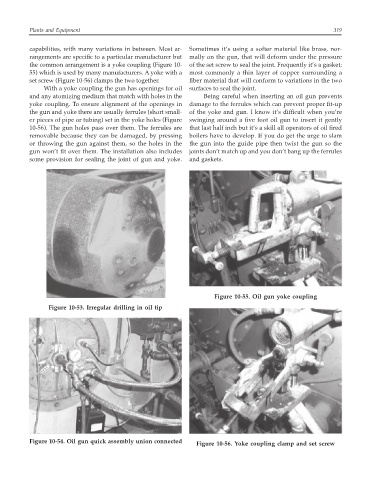

capabilities, with many variations in between. Most ar- Sometimes it’s using a softer material like brass, nor-

rangements are specific to a particular manufacturer but mally on the gun, that will deform under the pressure

the common arrangement is a yoke coupling (Figure 10- of the set screw to seal the joint. Frequently it’s a gasket;

55) which is used by many manufacturers. A yoke with a most commonly a thin layer of copper surrounding a

set screw (Figure 10-56) clamps the two together. fiber material that will conform to variations in the two

With a yoke coupling the gun has openings for oil surfaces to seal the joint.

and any atomizing medium that match with holes in the Being careful when inserting an oil gun prevents

yoke coupling. To ensure alignment of the openings in damage to the ferrules which can prevent proper fit-up

the gun and yoke there are usually ferrules (short small- of the yoke and gun. I know it’s difficult when you’re

er pieces of pipe or tubing) set in the yoke holes (Figure swinging around a five foot oil gun to insert it gently

10-56). The gun holes pass over them. The ferrules are that last half inch but it’s a skill all operators of oil fired

removable because they can be damaged, by pressing boilers have to develop. If you do get the urge to slam

or throwing the gun against them, so the holes in the the gun into the guide pipe then twist the gun so the

gun won’t fit over them. The installation also includes joints don’t match up and you don’t bang up the ferrules

some provision for sealing the joint of gun and yoke. and gaskets.

Figure 10-55. Oil gun yoke coupling

Figure 10-53. Irregular drilling in oil tip

Figure 10-54. Oil gun quick assembly union connected Figure 10-56. Yoke coupling clamp and set screw