Page 101 - Boiler plant and distribution system optimization manual

P. 101

86 Boiler Plant and Distribution System Optimization Manual

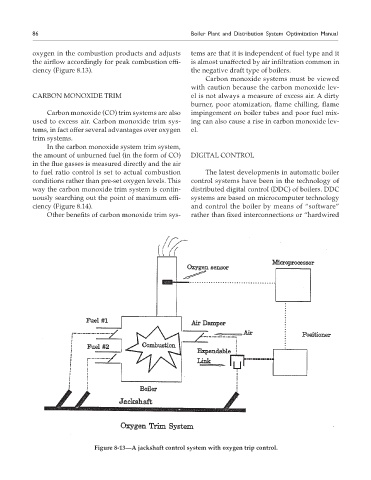

oxygen in the combustion products and adjusts tems are that it is independent of fuel type and it

the airflow accordingly for peak combustion effi- is almost unaffected by air infiltration common in

ciency (Figure 8.13). the negative draft type of boilers.

Carbon monoxide systems must be viewed

with caution because the carbon monoxide lev-

CARBON MONOxIDE TRIM el is not always a measure of excess air. A dirty

burner, poor atomization, flame chilling, flame

Carbon monoxide (CO) trim systems are also impingement on boiler tubes and poor fuel mix-

used to excess air. Carbon monoxide trim sys- ing can also cause a rise in carbon monoxide lev-

tems, in fact offer several advantages over oxygen el.

trim systems.

In the carbon monoxide system trim system,

the amount of unburned fuel (in the form of CO) DIGITAL CONTROL

in the flue gasses is measured directly and the air

to fuel ratio control is set to actual combustion The latest developments in automatic boiler

conditions rather than pre-set oxygen levels. This control systems have been in the technology of

way the carbon monoxide trim system is contin- distributed digital control (DDC) of boilers. DDC

uously searching out the point of maximum effi- systems are based on microcomputer technology

ciency (Figure 8.14). and control the boiler by means of “software”

Other benefits of carbon monoxide trim sys- rather than fixed interconnections or “hardwired

Figure 8-13—A jackshaft control system with oxygen trip control.