Page 140 - Boiler plant and distribution system optimization manual

P. 140

Over 100 Ways to Improve Efficiency 125

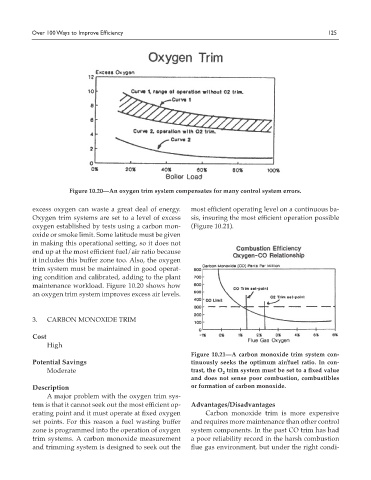

Figure 10.20—An oxygen trim system compensates for many control system errors.

excess oxygen can waste a great deal of energy. most efficient operating level on a continuous ba-

Oxygen trim systems are set to a level of excess sis, insuring the most efficient operation possible

oxygen established by tests using a carbon mon- (Figure 10.21).

oxide or smoke limit. Some latitude must be given

in making this operational setting, so it does not

end up at the most efficient fuel/air ratio because

it includes this buffer zone too. Also, the oxygen

trim system must be maintained in good operat-

ing condition and calibrated, adding to the plant

maintenance workload. Figure 10.20 shows how

an oxygen trim system improves excess air levels.

3. CARBON MONOxIDE TRIM

Cost

High

Figure 10.21—A carbon monoxide trim system con-

Potential Savings tinuously seeks the optimum air/fuel ratio. In con-

Moderate trast, the O trim system must be set to a fixed value

2

and does not sense poor combustion, combustibles

Description or formation of carbon monoxide.

A major problem with the oxygen trim sys-

tem is that it cannot seek out the most efficient op- Advantages/Disadvantages

erating point and it must operate at fixed oxygen Carbon monoxide trim is more expensive

set points. For this reason a fuel wasting buffer and requires more maintenance than other control

zone is programmed into the operation of oxygen system components. In the past CO trim has had

trim systems. A carbon monoxide measurement a poor reliability record in the harsh combustion

and trimming system is designed to seek out the flue gas environment, but under the right condi-