Page 145 - Boiler plant and distribution system optimization manual

P. 145

130 Boiler Plant and Distribution System Optimization Manual

Description umes of high temperature exhaust gasses. Years

When a boiler isn’t firing, a great deal of en- ago, slots were cut in the stack and metal damp-

ergy can be lost up the stack due to the chimney ers inserted, but these often were unsatisfactory.

effect when the lighter hot air formed in the boil- A modern adjustable design has been developed,

er internals and in the hot stack pull cold air in a special exhaust gas buffer that has shown good

through the boiler. This situation is most common results (Figure 10.29).

on atmospheric burner units, but may be present

on some older equipment too. Advantages/disadvantages

A damper automatically closes off the stack This inexpensive device can slow down the

when the boiler isn’t firing, holding the heat in escape of hot gases up the stack. It can also be

the boiler (Figure 10.28). adjusted to a specific location.

Advantages/Disadvantages

Stack dampers have full safety approval and

should be installed to curb this unnecessary loss.

10. SLOW DOWN ExHAUST FLOW

Cost

Low

10. Savings

Moderate to low

Description

In many cases the size of stacks and exhaust

systems is excessive allowing unrestricted and

often excessive negative draft “draw” to exist.

Oversized exhaust systems offer little resistance

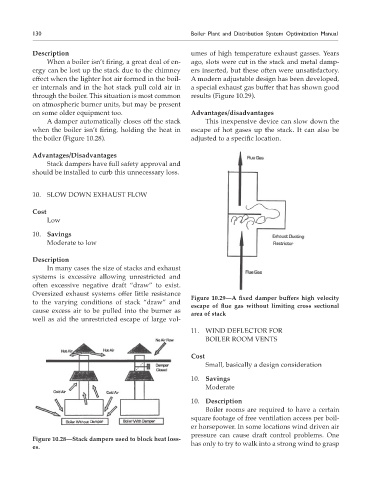

Figure 10.29—A fixed damper buffers high velocity

to the varying conditions of stack “draw” and

escape of flue gas without limiting cross sectional

cause excess air to be pulled into the burner as

area of stack

well as aid the unrestricted escape of large vol-

11. WIND DEFLECTOR FOR

BOILER ROOM VENTS

Cost

Small, basically a design consideration

10. Savings

Moderate

10. Description

Boiler rooms are required to have a certain

square footage of free ventilation access per boil-

er horsepower. In some locations wind driven air

pressure can cause draft control problems. One

Figure 10.28—Stack dampers used to block heat loss-

has only to try to walk into a strong wind to grasp

es.