Page 142 - Boiler plant and distribution system optimization manual

P. 142

Over 100 Ways to Improve Efficiency 127

5. CHARACTERIzABLE FUEL VALVE

Cost

Low

Potential Savings

2% to 12%

Description

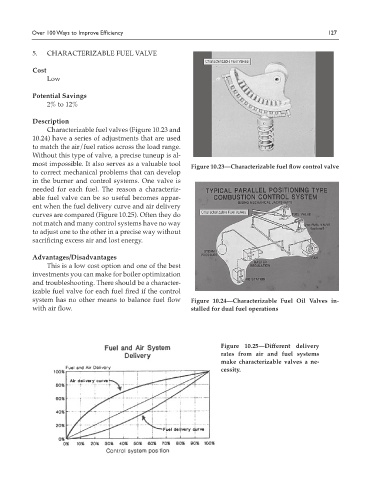

Characterizable fuel valves (Figure 10.23 and

10.24) have a series of adjustments that are used

to match the air/fuel ratios across the load range.

Without this type of valve, a precise tuneup is al-

most impossible. It also serves as a valuable tool

Figure 10.23—Characterizable fuel flow control valve

to correct mechanical problems that can develop

in the burner and control systems. One valve is

needed for each fuel. The reason a characteriz-

able fuel valve can be so useful becomes appar-

ent when the fuel delivery curve and air delivery

curves are compared (Figure 10.25). Often they do

not match and many control systems have no way

to adjust one to the other in a precise way without

sacrificing excess air and lost energy.

Advantages/Disadvantages

This is a low cost option and one of the best

investments you can make for boiler optimization

and troubleshooting. There should be a character-

izable fuel valve for each fuel fired if the control

system has no other means to balance fuel flow Figure 10.24—Characterizable Fuel Oil valves in-

with air flow. stalled for dual fuel operations

Figure 10.25—Different delivery

rates from air and fuel systems

make characterizable valves a ne-

cessity.