Page 147 - Boiler plant and distribution system optimization manual

P. 147

132 Boiler Plant and Distribution System Optimization Manual

15. OIL-WATER EMULSIONS 16. REPLACE ATMOSPHERIC

BURNERS WITH POWER BURNERS

Cost

Moderate Cost

Moderate

Potential Savings

Low Potential Savings

Moderate

Description

This is a process where very small amounts Description

of water, usually less than 6% of the fuel, of mi- An atmospheric type of burner has practical-

cron sized droplets are evenly mixed with fuel to ly no excess air control and loses a lot of heat up

cause additional atomization action in the com- the stack during the off cycle if a damper is not

bustion zone. (Figure 10.30) installed. On the other hand, excess air and stack

The benefit from oil/water emulsions is lim- losses can be more easily controlled with a power

ited, but is of great value in those plants where burner which has electrically positioned control

serious burner problems are causing smoke and linkage, motor driven fans and automatic damp-

excessive particulate emissions. When exposed to ers.

the intense heat in the fire box, the micron sized

droplets of water expand rapidly causing the oil Advantages/Disadvantages

droplets to break into smaller particles, enhanc- Atmospheric type burners have no excess

ing atomization. This reduces the smoke level al- air control. Excess air levels have often been mea-

lowing lower excess air and the elimination of the sured at extremely high levels. In addition, be-

sooting of the heat exchange surfaces. cause they use air that is pulled into the combus-

tion zone by the chimney effect there is no pos-

Advantages/disadvantages itive way to prevent cold air from being sucked

This is an effective way to reduce particu- through the boiler when it is not firing, which

late generation and change the smoke threshold wastes a lot of energy up the stack. A power burn-

so less excess air can be used. The equipment is er has two clear advantages, it can be adjusted for

expensive and the water used in this process es- excess air control and its dampers close during

capes up the stack carrying away a high level of the off cycle, keeping heat in the boiler.

energy.

17. FLAME RETENTION HEAD

TYPE BURNERS

Cost

Moderate

Savings

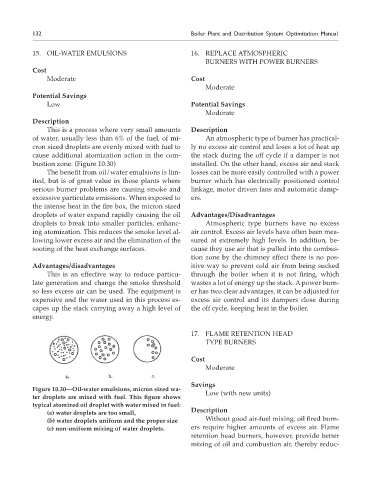

Figure 10.30—Oil-water emulsions, micron sized wa-

ter droplets are mixed with fuel. This figure shows Low (with new units)

typical atomized oil droplet with water mixed in fuel:

(a) water droplets are too small, Description

(b) water droplets uniform and the proper size Without good air-fuel mixing, oil fired burn-

(c) non-uniform mixing of water droplets. ers require higher amounts of excess air. Flame

retention head burners, however, provide better

mixing of oil and combustion air, thereby reduc-