Page 29 - Boiler plant and distribution system optimization manual

P. 29

14 Boiler Plant and Distribution System Optimization Manual

the steam pressure on a boiler not connected to a set at the wide open position. In the absence of

header system, the steam line should be warmed a non-return valve, the boiler stop valve should

up along with the boiler by the operation of drain be opened slowly when the pressure in the boiler

valves to remove condensation and create the de- and header are approximately equal.

sired flow of warming steam.

In bringing a boiler on the line with other

boilers on a header system, certain precautions WARM-UP

are necessary to avoid water hammer and exces-

sive temperature gradients in the piping. Ade- During the period when steam pressure is

quate drainage and warming of the piping will initially being raised, the boiler, especially the

eliminate the risk of water hammer. The judicious boiler drum which is fabricated from thick metal,

use of bypass valves around main header valves can experience some unusual and possibly dam-

will avoid steep temperature gradients. Header aging stresses. To avoid thermal stress, tempera-

drains should be operated. The steam line from ture changes should be limited. Figure 1.16 is a

the boiler to the· header should be brought up typical chart governing pressure raising in drum

to temperature by operating bypass and drain boilers. These temperature limitations are very

valves. When up to temperature and line pres- critical during the startup and shutdown of the

sure, the header valve may be opened wide and boiler. They are necessary to minimize thermal

the bypass closed. The stem for the non-return stress in the steam drum. Temperature changes

valve should be back off to a position correspond- can be controlled by controlling the firing rate on

ing to about 25% open until the boiler begins to startup and controlling the cooling down of the

supply steam to the header, after which it can be boiler when shutting down. Your boiler may be

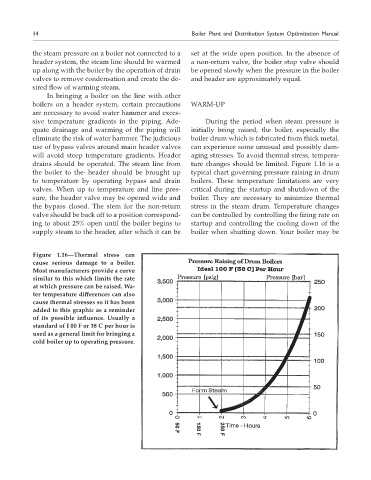

Figure 1.16—Thermal stress can

cause serious damage to a boiler.

Most manufacturers provide a curve

similar to this which limits the rate

at which pressure can be raised. Wa-

ter temperature differences can also

cause thermal stresses so it has been

added to this graphic as a reminder

of its possible influence. Usually a

standard of I 00 F or 38 C per hour is

used as a general limit for bringing a

cold boiler up to operating pressure.