Page 26 - Boiler plant and distribution system optimization manual

P. 26

Boiler Plant Orientation 11

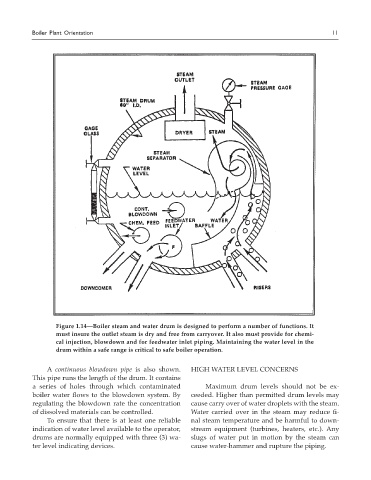

Figure 1.14—Boiler steam and water drum is designed to perform a number of functions. It

must insure the outlet steam is dry and free from carryover. It also must provide for chemi-

cal injection, blowdown and for feedwater inlet piping. Maintaining the water level in the

drum within a safe range is critical to safe boiler operation.

A continuous blowdown pipe is also shown. HIGH WATER LEVEL CONCERNS

This pipe runs the length of the drum. It contains

a series of holes through which contaminated Maximum drum levels should not be ex-

boiler water flows to the blowdown system. By ceeded. Higher than permitted drum levels may

regulating the blowdown rate the concentration cause carry over of water droplets with the steam.

of dissolved materials can be controlled. Water carried over in the steam may reduce fi-

To ensure that there is at least one reliable nal steam temperature and be harmful to down-

indication of water level available to the operator, stream equipment (turbines, heaters, etc.). Any

drums are normally equipped with three (3) wa- slugs of water put in motion by the steam can

ter level indicating devices. cause water-hammer and rupture the piping.