Page 126 - Building A Succesful Board-Test Strategy

P. 126

112 BUILDING A SUCCESSFUL BOARD-TEST STRATEGY

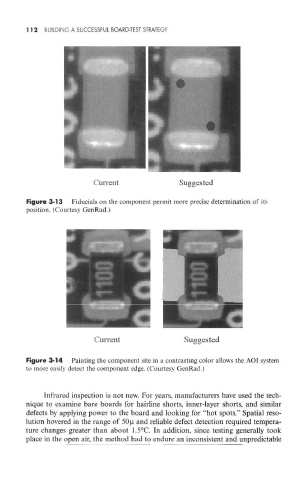

Figure 3-13 Fiducials on the component permit more precise determination of its

position. (Courtesy GenRad.)

Figure 3-14 Painting the component site in a contrasting color allows the AOI system

to more easily detect the component edge. (Courtesy GenRad.)

Infrared inspection is not new. For years, manufacturers have used the tech-

nique to examine bare boards for hairline shorts, inner-layer shorts, and similar

defects by applying power to the board and looking for "hot spots." Spatial reso-

lution hovered in the range of 50 p, and reliable defect detection required tempera-

ture changes greater than about 1.5°C. In addition, since testing generally took

place in the open air, the method had to endure an inconsistent and unpredictable