Page 129 - Building A Succesful Board-Test Strategy

P. 129

Inspection as Test 115

3,3.4.3 The Infrared Test Process

To build the good-board model, a test engineer views a computer image of

the board, highlights each component and area of interest with the computer's

mouse, identifies the component, and enters other pertinent data. From this infor-

mation and a user-supplied input pattern that mimics the board's actual operation,

the system assembles a database.

Next, an operator feeds production boards to the system, positioning each

board's tooling holes on matching tooling pins in the isothermal chamber. The

tooling pins and I/O connectors represent the only "fixture" that the method requires.

Each board generates a set of infrared images when executing the test pattern. A

statistical analysis of the resulting signatures produces the standard against which

the system will measure each board during testing. The tester will flag any uncovered

outliers in the sample as bad boards, and does not include them in the standard.

The production test itself is relatively straightforward. An operator puts a

board into the isothermal chamber, positions it on the tooling pins, and connects

the edge connector and any other connectors. After reading the ambient infrared

image, the tester powers up the board very briefly (to prevent any shorts from frying

it) and again examines its thermal signature. Image-analysis software compares this

result to the good-board signature and makes a go/no-go decision. Shorts (includ-

ing power-to-ground shorts, which are nearly undetectable by conventional test)

show up as statistically significant temperature differences at particular board loca-

tions, as in Figure 3-1.6. A failing board at this stage would proceed to repair before

continuing, as with both in-circuit and functional test.

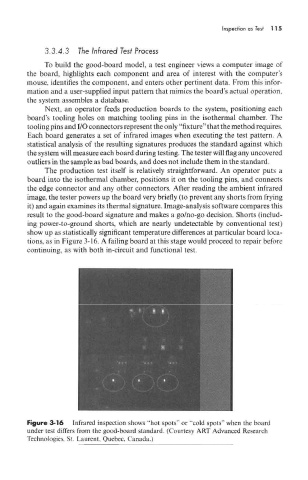

Figure 3-16 Infrared inspection shows "hot spots" or "cold spots" when the board

under test differs from the good-board standard. (Courtesy ART Advanced Research

Technologies, St. Laurent, Quebec, Canada.)