Page 269 - Buried Pipe Design

P. 269

240 Chapter Four

PA r

T = PA

b T = PA

PA PA

b

Dead end

PA r

PA r

Tee

T = PA b

PA 2 PA 1

PA

b

T = P (A –A )

1

2

PA

Reducer r

Wye

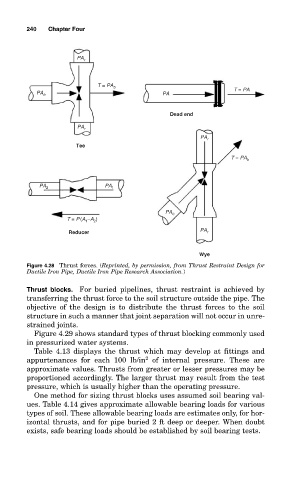

Figure 4.28 Thrust forces. (Reprinted, by permission, from Thrust Restraint Design for

Ductile Iron Pipe, Ductile Iron Pipe Research Association.)

Thrust blocks. For buried pipelines, thrust restraint is achieved by

transferring the thrust force to the soil structure outside the pipe. The

objective of the design is to distribute the thrust forces to the soil

structure in such a manner that joint separation will not occur in unre-

strained joints.

Figure 4.29 shows standard types of thrust blocking commonly used

in pressurized water systems.

Table 4.13 displays the thrust which may develop at fittings and

2

appurtenances for each 100 lb/in of internal pressure. These are

approximate values. Thrusts from greater or lesser pressures may be

proportioned accordingly. The larger thrust may result from the test

pressure, which is usually higher than the operating pressure.

One method for sizing thrust blocks uses assumed soil bearing val-

ues. Table 4.14 gives approximate allowable bearing loads for various

types of soil. These allowable bearing loads are estimates only, for hor-

izontal thrusts, and for pipe buried 2 ft deep or deeper. When doubt

exists, safe bearing loads should be established by soil bearing tests.