Page 271 - Buried Pipe Design

P. 271

242 Chapter Four

TABLE 4.14 Estimated Bearing Load

Soil type lb/ft 2

Muck, peat, etc. 0

Soft clay 500

Sand 1000

Sand and gravel 1500

Sand and gravel with clay 2000

Sand and gravel cemented with clay 4000

Hard pan 5000

The design calculation of a thrust block is illustrated in the next

example

Example Problem 4.3 Required is thrust block at 10-in 90 elbow.

Maximum test pressure is 200 lb/in . Soil type is sand and gravel with clay.

2

■ Calculate thrust. From Table 4.13, thrust on 10-in 90 elbow is 13,680 lb

per 100 lb/in operating pressure. Total thrust 2 (13,680) 27,360 lb.

2

■ Calculate thrust block size. From Table 4.14, safe bearing load for sand and

gravel and clay is 2000 lb/ft ; total thrust support area 27,360/2000

2

2

13.68 ft .

■ Select type of thrust block. From Fig. 4.29, select type 3.

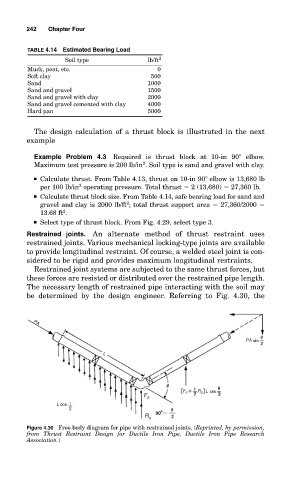

Restrained joints. An alternate method of thrust restraint uses

restrained joints. Various mechanical locking-type joints are available

to provide longitudinal restraint. Of course, a welded steel joint is con-

sidered to be rigid and provides maximum longitudinal restraints.

Restrained joint systems are subjected to the same thrust forces, but

these forces are resisted or distributed over the restrained pipe length.

The necessary length of restrained pipe interacting with the soil may

be determined by the design engineer. Referring to Fig. 4.30, the

PA

PA

L

[ F s + R s L ]

F s

L cos 1

2

R s

Figure 4.30 Free-body diagram for pipe with restrained joints. (Reprinted, by permission,

from Thrust Restraint Design for Ductile Iron Pipe, Ductile Iron Pipe Research

Association.)